Log in or Sign up

You are using an out of date browser. It may not display this or other websites correctly. You should upgrade or use an alternative browser .

Re-tabbing Bulkheads on a Production Catamaran

Discussion in ' Multihulls ' started by Coastal Ogre , Jun 28, 2019 .

Coastal Ogre Junior Member

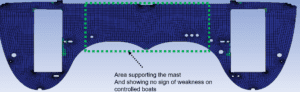

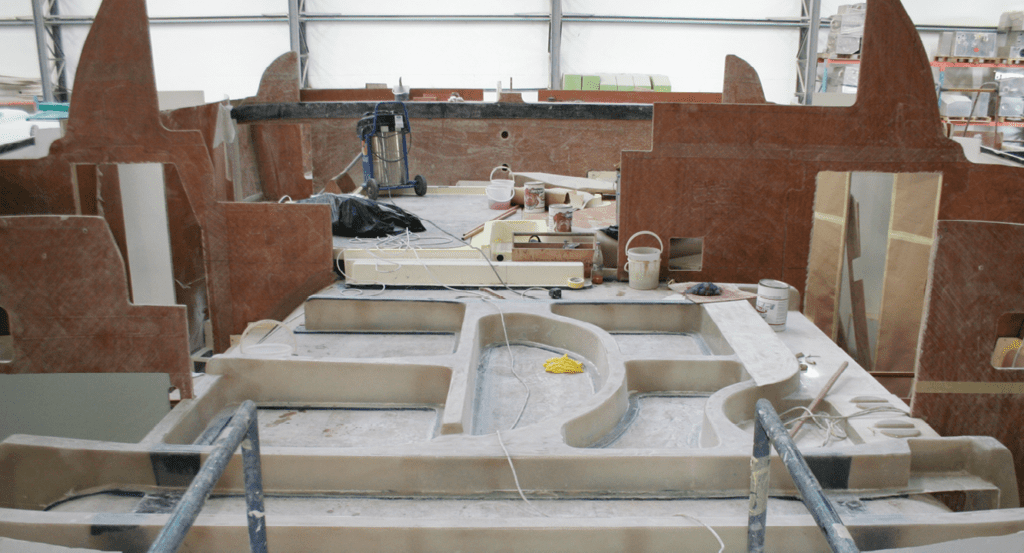

Ready Thy Archers! Hello everyone and welcome to the weekend. As a new member I thought I might ask for some collective wisdom. Even though I have already conducted personal research on this site and others, I still would appreciate some feedback for my particular situation. Background: 38 foot (11.55 m) European production catamaran that was built in 2003. Solid polyester/vinylester hull below the waterline with core on the sides above the waterline and a balsa cored deck (note, I still need to open up a section and positively identify the core material used in the side hulls, but let’s say balsa for now). Dry ship is listed at 7,260 kg in the documents and when we last had her weighed during haul out in Grenada the lift operator said just over 10,000 kg (so she’s running heavy). I also know that when dealing with some thru hulls back in 2013 that the solid hull thickness is just shy of 25 mm along the bottom. I am the second owner, after buying her out of charter in 2007 – so she did a little less than 3 years in the BVI charter trade. Problem statement: After numerous years of full-time cruising in the Caribbean, we have noticed that many of the smaller bulkheads and furniture paneling has separated from the hull. This specific manufacturer has a history of poor varnish application and service life. Finally, after one too many rough passages, we began to notice that some of the glue joints (it is believed to be Plexus, but if anyone knows what was being used in France back in 2003 please let me know) have failed at the wood interface. It is only the wood interface that the adhesive has failed. During some destructive testing, I did observe that the bulkheads were varnished prior to tabbing and that the varnish under the fillet has lifted from the wood, thus creating a tabbing failure (through no fault of the actual adhesive). See picture #1 for an example. At this time, in light of my inspections, all of my issues are with what I would characterize as non-structural bulkheads. But any chance I get to stiffen (and lighten) her up is envisioned and desirable. There are four bulkheads that I would say are structural and they are tabbed with glass with an air gap of “x” mm (as I still need to measure that). My repairs will be using West System epoxy, because that’s what I’m familiar with. Although this cat is far from perfect, I am attached to her. And I have plans on making more memories in the future onboard… even if it does mean slipping down more 20’ waves during a gale because we got a bad weather forecast So here are my initial questions in reference to the cartoon shown in picture #2: 1. I am not sure if I will re-use the marine ply or fabricate composite panels (I’m really leaning to composite right now). Either way should I provide a cove profile on the edges of the bulkheads as shown? And is there a recommended radius for this feature? Is there an industry ratio of bulkhead thickness to cove radius? 2. What type of bedding compound? I see everything from thickened epoxy to commercial offerings. Knowing that we see some flex (if only because of my luck for rough weather), so advice on which is appropriate for a semi-flexible environment? I see Arjay 4001 has many claims about how flexible they are… 3. Use the bedding compound only between bulkhead & hull or use a foam strip between to prevent stress risers? And if foam is recommended for this situations what dimensions are we talking about here and what type of foam and density? 4. An older thread on this site seemed to recommend a 4 mm standoff between bulkheads and the hulls. Many authors echoed that that ‘sounded right’ but what is the rationale behind 4 mm (as opposed to say 3 or 5 mm)? And is it appropriate to have a standoff at all in my situation if large fillets are used? Note in picture #1 there is no gap in this construction (and thankfully no detectable cracks either). 5. If a standoff of “x” mm is desirable, would it be acceptable (to a future marine surveyor) to use the bedding compound between the bulkhead edge & hull and create the fillets all at once? Therefore eliminating the air gap and use of foam strip? 6. Should I glass in a continuous length of tape on the hull under the bulkhead edge prior to installation (for both solid hull and cored hull portions) for these smaller bulkheads? I notice 150 mm wide tape is often referred to in this context, but what is the rationale? Is it an industry standard or experience says it’s vastly better than say 100 mm wide tape? 7. Tape used in tabbing over the fillets – use how many layers for a non-structural bulkhead and with what thicknesses and which order? I have noticed that in some web discussions it is/was permissible to start with the widest tape first and use smaller tapes over the top when using epoxy resins (but apparently not polyester). Although no real reason was given as to ‘why’. 8. Thoughts on removing the existing adhesive? Chisel or oscillating multi-tool? Or…? 9. Any professional references for me? I’m not above paying for an experienced engineer to provide assistance (I’m in Northern Florida). I am however, a bit hesitant as most I’ve talked with personally don’t seem to know multihulls in general (and that can get expensive fast). I did get one response from the designer of record about this issue and the response was: “Bulkhead attachment to the hull: You could have fill the gap between the bulkhead and the hull with charged resin, but it is not the main thing. You have to do again the bonding with 2*400gr/m² biaxial cloth taping between hull to the bulkhead.” Which I really appreciated. But I had many questions about the response and unfortunately did not get any follow-up. I can appreciate the delicate nature of the business as I’m sure they are always very cautious about litigation when giving email communications of this nature. OK, that’s it for now. Let those ‘arrows’ fly, I’ve got my ribs exposed! Thanks – Coastal Ogre

Attached Files:

Picture No 1.pdf

Picture No 2.pdf

oldmulti Senior Member

Coastal Orge. I am still thinking about this, but my initial reaction is how much work do you want to do and how much lighter will the result be. Yes a foam glass panel can be substituted and it will be half the weight of the ply bulkhead and probable save you 5 kgs of weight if the bulkhead is a square meter (10.7 square feet) in size. But the work to cut out the original, create and install the new panel with bog and tapes, cleanup and fair the surface of the tapes and make it make it look pretty is not trivial. On the Multihull Structure Thoughts thread are two C106.pdf's have bulkheads/ribs for a 40 foot cat (base design for original Catana 40). It gives a guide to suitable bulkhead materials and glass tapes. My focus on weight is in my experience before a racing series we would unload our boat and only put back the really required items, this pulled up to 600 kilo's out of the boat. Do you need that generator, inflatable dingy, portable fridge, unread books, spare blankets, extra rope etc. I will think more about how you may be able to repair, upgrade the existing structure and get back to you.

TeddyDiver Gollywobbler

Without knowing the excact structural design of your boat I'd tab all the bulkheads and paneling on the hull without gaps to get a solid monoqoque construction. There's online "Gougeon brother on boatbuilding", read it first and follow the instructions. PVC foam as Divinycell instead of ply to save weight for most places..

waikikin Senior Member

If the solid hull skin is already 25mm on the centreline the weight race already hard to catch up. Every little bit helps though. Personally I'd just accept that it's on the heavy side & just put back as built- with some multis just need to believe that they're better motor sailers than sailing machines and enjoy for the space & view. Generally the gap you mention is to avoid print to topsides, if epoxy and tabbed over a cove less issue. Jeff

oldmulti said: ↑ Coastal Orge. I am still thinking about this, but my initial reaction is how much work do you want to do and how much lighter will the result be. Yes a foam glass panel can be substituted and it will be half the weight of the ply bulkhead and probable save you 5 kgs of weight if the bulkhead is a square meter (10.7 square feet) in size. But the work to cut out the original, create and install the new panel with bog and tapes, cleanup and fair the surface of the tapes and make it make it look pretty is not trivial. On the Multihull Structure Thoughts thread are two C106.pdf's have bulkheads/ribs for a 40 foot cat (base design for original Catana 40). It gives a guide to suitable bulkhead materials and glass tapes. My focus on weight is in my experience before a racing series we would unload our boat and only put back the really required items, this pulled up to 600 kilo's out of the boat. Do you need that generator, inflatable dingy, portable fridge, unread books, spare blankets, extra rope etc. I will think more about how you may be able to repair, upgrade the existing structure and get back to you. Click to expand...

TeddyDiver said: ↑ Without knowing the excact structural design of your boat I'd tab all the bulkheads and paneling on the hull without gaps to get a solid monoqoque construction. There's online "Gougeon brother on boatbuilding", read it first and follow the instructions. PVC foam as Divinycell instead of ply to save weight for most places.. Click to expand...

waikikin said: ↑ If the solid hull skin is already 25mm on the centreline the weight race already hard to catch up. Every little bit helps though. Personally I'd just accept that it's on the heavy side & just put back as built- with some multis just need to believe that they're better motor sailers than sailing machines and enjoy for the space & view. Generally the gap you mention is to avoid print to topsides, if epoxy and tabbed over a cove less issue. Jeff Click to expand...

fastsailing Senior Member

Coastal Ogre said: ↑ Ready Thy Archers! Hello everyone and welcome to the weekend. As a new member I thought I might ask for some collective wisdom. Even though I have already conducted personal research on this site and others, I still would appreciate some feedback for my particular situation. Background: 38 foot (11.55 m) European production catamaran that was built in 2003. Solid polyester/vinylester hull below the waterline with core on the sides above the waterline and a balsa cored deck (note, I still need to open up a section and positively identify the core material used in the side hulls, but let’s say balsa for now). Dry ship is listed at 7,260 kg in the documents and when we last had her weighed during haul out in Grenada the lift operator said just over 10,000 kg (so she’s running heavy). I also know that when dealing with some thru hulls back in 2013 that the solid hull thickness is just shy of 25 mm along the bottom. I am the second owner, after buying her out of charter in 2007 – so she did a little less than 3 years in the BVI charter trade. Problem statement: After numerous years of full-time cruising in the Caribbean, we have noticed that many of the smaller bulkheads and furniture paneling has separated from the hull. This specific manufacturer has a history of poor varnish application and service life. Finally, after one too many rough passages, we began to notice that some of the glue joints (it is believed to be Plexus, but if anyone knows what was being used in France back in 2003 please let me know) have failed at the wood interface. It is only the wood interface that the adhesive has failed. During some destructive testing, I did observe that the bulkheads were varnished prior to tabbing and that the varnish under the fillet has lifted from the wood, thus creating a tabbing failure (through no fault of the actual adhesive). See picture #1 for an example. At this time, in light of my inspections, all of my issues are with what I would characterize as non-structural bulkheads. But any chance I get to stiffen (and lighten) her up is envisioned and desirable. There are four bulkheads that I would say are structural and they are tabbed with glass with an air gap of “x” mm (as I still need to measure that). My repairs will be using West System epoxy, because that’s what I’m familiar with. Although this cat is far from perfect, I am attached to her. And I have plans on making more memories in the future onboard… even if it does mean slipping down more 20’ waves during a gale because we got a bad weather forecast So here are my initial questions in reference to the cartoon shown in picture #2: 1. I am not sure if I will re-use the marine ply or fabricate composite panels (I’m really leaning to composite right now). Either way should I provide a cove profile on the edges of the bulkheads as shown? And is there a recommended radius for this feature? Is there an industry ratio of bulkhead thickness to cove radius? 2. What type of bedding compound? I see everything from thickened epoxy to commercial offerings. Knowing that we see some flex (if only because of my luck for rough weather), so advice on which is appropriate for a semi-flexible environment? I see Arjay 4001 has many claims about how flexible they are… 3. Use the bedding compound only between bulkhead & hull or use a foam strip between to prevent stress risers? And if foam is recommended for this situations what dimensions are we talking about here and what type of foam and density? 4. An older thread on this site seemed to recommend a 4 mm standoff between bulkheads and the hulls. Many authors echoed that that ‘sounded right’ but what is the rationale behind 4 mm (as opposed to say 3 or 5 mm)? And is it appropriate to have a standoff at all in my situation if large fillets are used? Note in picture #1 there is no gap in this construction (and thankfully no detectable cracks either). 5. If a standoff of “x” mm is desirable, would it be acceptable (to a future marine surveyor) to use the bedding compound between the bulkhead edge & hull and create the fillets all at once? Therefore eliminating the air gap and use of foam strip? 6. Should I glass in a continuous length of tape on the hull under the bulkhead edge prior to installation (for both solid hull and cored hull portions) for these smaller bulkheads? I notice 150 mm wide tape is often referred to in this context, but what is the rationale? Is it an industry standard or experience says it’s vastly better than say 100 mm wide tape? 7. Tape used in tabbing over the fillets – use how many layers for a non-structural bulkhead and with what thicknesses and which order? I have noticed that in some web discussions it is/was permissible to start with the widest tape first and use smaller tapes over the top when using epoxy resins (but apparently not polyester). Although no real reason was given as to ‘why’. 8. Thoughts on removing the existing adhesive? Chisel or oscillating multi-tool? Or…? 9. Any professional references for me? I’m not above paying for an experienced engineer to provide assistance (I’m in Northern Florida). I am however, a bit hesitant as most I’ve talked with personally don’t seem to know multihulls in general (and that can get expensive fast). I did get one response from the designer of record about this issue and the response was: “Bulkhead attachment to the hull: You could have fill the gap between the bulkhead and the hull with charged resin, but it is not the main thing. You have to do again the bonding with 2*400gr/m² biaxial cloth taping between hull to the bulkhead.” Which I really appreciated. But I had many questions about the response and unfortunately did not get any follow-up. I can appreciate the delicate nature of the business as I’m sure they are always very cautious about litigation when giving email communications of this nature. OK, that’s it for now. Let those ‘arrows’ fly, I’ve got my ribs exposed! Thanks – Coastal Ogre Click to expand...

fastsailing: thanks for this insight, it is much appreciated. 1.,2., and 3. - all good! 4. - I got everything except for that part in bold. Are you saying 'use only one layer of cloth to tab the non-structural bulkheads, so they can flex?' Because the wording in 7. seems to contradict that point (would prefer three layers). 5.,6.,7., and 8. - all good! p.s. - agreed, and I should have been more clear in my wording. I knew the thickness along the bottom area (close to the fixed keels), but I have no direct evidence elsewhere (at this time). p.p.s. - all good! Regards - Coastal Ogre

Coastal Ogre said: ↑ fastsailing: thanks for this insight, it is much appreciated. 1.,2., and 3. - all good! 4. - I got everything except for that part in bold. Are you saying 'use only one layer of cloth to tab the non-structural bulkheads, so they can flex?' Because the wording in 7. seems to contradict that point (would prefer three layers). 5.,6.,7., and 8. - all good! p.s. - agreed, and I should have been more clear in my wording. I knew the thickness along the bottom area (close to the fixed keels), but I have no direct evidence elsewhere (at this time). p.p.s. - all good! Regards - Coastal Ogre Click to expand...

- Advertisement:

fastsailing: thanks for your help and explanation! Regards - Coastal Ogre

Using aluminiun masts sections as tranverse structure instead of bulkheads

Distance between bulkheads

- No, create an account now.

- Yes, my password is:

- Forgot your password?

Are Leopard Catamarans Good? A Complete Review

As an Amazon Associate, we earn from qualifying purchases. We may also earn commissions if you purchase products from other retailers after clicking on a link from our site.

Catamarans are popular with boat owners due to their excellent performance, stability, comfort, and airy living spaces. Leopard catamarans boast a long tradition of producing easy-to-handle vessels with spacious layouts and superior cruising capabilities. You’ve probably heard a thing or two about these popular boats, but let’s get the real deal about them in this review.

Leopard catamarans are good because they are robust, spacious, well-built, and deliver an exceptional cruising performance. These cats are excellent for ocean crossings since they are safe, easy to handle, and fast. The main downside is that they are expensive.

Throughout this article, you’ll also discover the following about Leopard catamarans:

- The pros and cons of these catamarans

- How they compare with similar catamaran brands

- Frequently asked questions about Leopard catamarans plus their answers

Why You Might Want To Consider Getting a Leopard Catamaran

If you are in the market for a sailing catamaran, you may want to have a Leopard Catamaran among the options to consider. These ruggedly-built vessels are roomy, robust, and deliver superior cruising performance – some of the many reasons that would make any sailor want to get their hands on one.

To understand more about these unique vessels, let’s take a closer look at some of the benefits of owning a Leopard Catamaran.

They Boast a Solid Construction

Leopard Catamaran boats boast a superior and solid construction using advanced materials such as infused glass or PVC core construction. The boats come in innovative designs meant to be appealing, fun, spacious, and comfortable. Capable of ocean crossings, these sea-worthy blue water cruise boats have superb build quality, and they sail all over the world .

Robertson & Caine Factory in South Africa, producers of world-acclaimed racers and cruisers, are the boat builders behind Leopard Catamarans. These innovative, high-quality multihulls are serious contenders in the global catamaran market and enjoy dominance as the best-selling catamaran brand in North America. Indeed many Leopard cat owners are pretty happy with their model’s performance.

Balsa-cored hulls and decks characterize these boats. This feature helps to provide maximum firmness while keeping weight to the minimum. In addition, solid fiberglass appears in all places with mounted hardware.

Leopard catamarans provide one of the best examples of compromise between sail performance and interior volume. The hulls feature fine entry points and are deep and narrow beneath the waterline for enhanced performance in all conditions. However, they curve higher up to provide more accommodation space in the cabins and ample deck space.

Most of the boats have shallow keels and are packed full of closed-cell polyurethane foam that helps boost buoyancy as well as hinder water ingress . Furthermore, both the stern and bow feature watertight bulkheads that play a crucial role in keeping out water in the unlikely event of a collision. The bulkheads thus go a long way in enhancing the vessel’s safety.

Leopard Catamaran Boats Are Extremely Well-Built

If you are looking for a practical, efficient design and a stable platform, then you can’t go wrong with a Leopard Catamaran. Everything is laid out thoughtfully and logically in a way that makes perfect sense. For instance, the layout, starting from the helm placement, engine set up to the winches, is simple, well-organized, and easy to understand.

Unlike most production catamarans that don’t offer great finishing touches, Leopard Catamarans are in a class of their own. Not only are the boats appealing and beautifully designed, but their finishing is also top-notch and depicts keen attention to detail. You will be hard-pressed to find exposed plywood in the drawers or nails that stick out. Instead, what you will find are sleek, luxurious finishes.

Everything on the Leopard cat is easily accessible through panels. The top-quality components also bear clear labels making them easy to identify. Better yet, the raised helm station provides panoramic visibility with sight lines clear and unobstructed and quick access to winches and sheets. An accompanying manual is at hand to offer wiring, plumbing, and mechanical diagrams, and all the parts are readily available.

They Deliver a Great Performance

These boats come with a robust sail plan that allows for good sailing speeds. They are quite reliable, and their simple systems ensure that the boats perform admirably in all wind conditions, whether in a marina or out in the ocean.

The efficient hulls deliver maximum speeds of 24knots+ (44.4 km/hr) and cruising speeds of 18knots ( 33.3 km/hr). This translates to lower fuel consumption, less horsepower, and a much longer range than similar sized power catamarans.

It’s important to note here that most catamaran buyers are first-time owners looking at their catamarans as second homes. As such, they are far more concerned with their comfort at anchor than speed underway.

They Are Spacious and Comfortable

A Leopard Catamaran boat is built to provide optimal livability and adequate space for both friends and family. And for those who choose to live onboard, it’s the perfect home away from home. The boat’s easy-to-handle features and handholds offer immense practicality and enhanced safety for those sailors desiring to venture out on long cruising voyages or ocean crossings.

The boat’s spacious cabins are both functional and comfortable. They offer adequate storage space in cabinets, under the beds, and on the floor. The galley has favorable spacing, too, including large counter spaces, and can accommodate more than one person at a time without a hassle.

To ensure lower resistance and less pitching motion, these vessels come with sharp bows. Also, the transoms are wide and offer excellent access to the water, while wide aft sections allow optimal load carrying.

The rock-solid hulls provide superior bridge deck clearance , which is critical for many boat owners. What this means is that you hardly hear slamming except in stormy weather. The anchoring system has a suitably concealed location on the forward deck, thus preventing rust, mud, and fouling of chain on hulls. And depending on the weather, the main saloon can either open or close to the aft cockpit.

No-maintenance hard tops cover the aft and forward cockpits and the helm station, thus providing protection from extreme sunny conditions.

The Boats Offer Excellent Social Areas

A Leopard Catamaran comes with two areas that are suitable for all your social needs; the forward cockpit and the topside lounge. The large, well-laid cockpit offers direct access into the main saloon and presents an excellent area for kicking back and relaxing due to its lavish spacing. The opportunity to have fresh flowing air throughout the boat is delightful.

In addition, it allows direct access to the transoms as well as adequate room for dive tanks, a BBQ, and additional tankage. You can enjoy incredible sunrises or sunsets here as well as privacy while in marinas or at anchor, not to mention the excellent ventilation.

The other superb social spot is the spacious lounge space which comes equipped with permanently fixed cushions and tables. This space offers an additional area for all your socializing and entertaining. Located at the roof, the lounge provides great visibility, plus you can access it directly from the deck.

This lounge poses no interference with the helm station, and you can still communicate with the latter from here. What’s more, it’s perfectly safe to stay here while the vessel is under sail. You can choose to spend quiet evenings relaxing or listening to music at anchor.

They Are High on Safety

A great plus with these catamarans is that they come with in-built safety features. For starters, the forward cockpit provides a natural, safe zone for you and your family to sit and enjoy your breakfast as you watch the horizon. You don’t have to worry about your kids going on deck untethered.

Secondly, every line comes back to the helm. This well-thought-out safety feature means that you can control everything on the boat from the helm station. Hence, you never have to be out there in foul weather adjusting the sails.

Again, the centrally-located helm station provides additional safety, and the person on sailing watch does not get cut off from the rest of the people. In any case, having the helm station placed towards the edge of the boat is not safe since it makes overnight passage in rough seas rather dangerous.

Overall, the high-quality construction plus outstanding stability in a wide range of sea conditions make you feel safe at all times.

They Are Comfortable in All Conditions

Leopard Catamarans are comfy while out at sea and anchor. They come designed in such a way that the door to the forward access plus the sliding glass door aft maintain a steady and comfortable airflow. Furthermore, the protected helm station is quite useful when the flybridge gets too cold, or there’s pouring rain.

Featuring a wide array of creature comforts, the cruising vessels provide you with access to amenities such as a large and efficient refrigerator and freezer, ice maker, washing machine, water storage, and air conditioning. The expansive living spaces are also quite appealing to live-aboard cruising families and couples.

They Are Easy To Handle

You can sail a Leopard Catamaran single-handed. This feature endears these sailing vessels to many sailors who might prefer minimal crew or to have a boat all to themselves. Moreover, the dedicated, well-protected helm station comes specially designed for offshore single-handed sailing, while rudder positioning behind the prop allows for better maneuverability.

The helm station provides direct access plus visibility to the aft cockpit as well as ready access to the foredeck and side decks. You also get full visibility to the upper lounge, stearns and bows, and the mainsail through the skylight.

The Boats Have a High Resale Value

Both chartered and privately-owned Leopard catamarans offer a high resale value though owner version catamarans tend to command a much higher price. This is primarily due to their comfort and ease of handling. The Leopard Catamarans brand is also well-known thanks to their award-winning models.

Leopard Catamarans Are Easy To Maintain

Leopard cats are pretty easy to maintain and only require regular cleaning and routine maintenance to remain in good working condition. The boats have easy-to-clean interiors and exteriors, which makes this routine maintenance less of a chore.

Additionally, boat parts are easily available given the standardized systems across the Leopard line of boats and the considerable quantities the company manufactures. You can replace most of the parts on your own, too, if you have mechanical skills.

As an owner, you also get support at any corner of the world as Leopard Catamarans has offices and bases worldwide.

Downsides of Leopard Catamarans

Some of the disadvantages of Leopard Catamarans boats include the following:

- They tend to be more expensive than other catamaran brands.

- Balsa-cored boats tend to suffer moisture incursion. Hence it would be best if you inspected deck fittings regularly.

- Some boats experienced structural issues on the aft bulkhead and between the saloon and cockpit in the areas above the door frame.

- The saloon seat cushions are too narrow, soft, and slippery in some models.

How To Maintain Your Leopard Catamaran

A well-maintained Leopard Catamaran can last for many years. But that’s not all. Following basic yacht maintenance rules ensures that your boat doesn’t depreciate , thus fetching you a better price if you decide to upgrade. To keep your vessel in top condition, follow the below suggestions:

- Keep your Leopard Catamaran clean and updated with routine maintenance. Wash the boat, keep it clean, tidy, and well-organized, and don’t forget to conduct oil, fuel, filter, and zinc changes. Ensure to keep the stainless steel appliances clean and lubricate equipment like the wrenches, autopilot, lines, and rigging to avoid rust buildup.

- Install solar panels plus a wind generator. This is especially key if you plan on going on long cruises since it allows you to be more self-supporting while at anchor.

- Conduct preventive maintenance. This includes fixing window seals to prevent leaks and replacing recurrent wear items such as the rigging, anchor chain, sails, and seadek.

- Consider doing upgrades to make your boat more comfortable, stylish, and even more marketable. These include items such as electronics, air conditioning, upholstery, and the engine.

Here is a video giving a detailed look into the kind of maintenance costs you might incur with your Leopard Catamaran:

Here are some of the most frequently asked questions about Leopard Catamarans, plus their answers:

Is a Forward Cockpit Safe for Long Passages?

Yes, the boat is safe for ocean crossings. A Leopard Catamarans forward cockpit comes with a sealed hatch that prevents water from getting inside. Furthermore, the space has numerous structured openings that allow any storm waters that get in to drain out super fast.

Is It Possible To Sail a Leopard Catamaran on Your Own?

Yes, it is. All lines lead back to the helm station so you can control everything on the boat from a single point. The presence of two independent engines and propellers also makes it easier to maneuver the boat, particularly in a marina.

Can a Leopard Catamaran Sail Fast?

A Leopard Catamaran is designed for cruising. Therefore, the boat might sacrifice some level of performance for the comfort of the owner and his family or guests. However, this boat is still faster than a similar-sized monohull though upwind journeys might be slower due to a lower capacity to point towards the wind.

Can a Leopard Catamaran Cross the Ocean?

Most certainly! These great vessels are not only safe, stable, and fast, but they are also capable of taking long cruises and ocean crossings. What’s more, they have the fuel and water storage capacity to allow for such an undertaking.

What Is the Difference Between a Leopard Sail Catamaran and a Power Catamaran?

Sail catamarans like the Leopard 40, 45, 50, and 58 have additional space below for more convenience. This includes a lounge with a seating area, sunbed, and table, a well-protected helm station that’s integrated into the cockpit, and even a lounging flybridge accommodation.

Power Catamarans like the Leopard 39, 43, and 53 are mid-sized catamarans featuring the stepped hull design. This allows for more accommodation space without decreased yacht performance, tremendous speeds -up to 24 knots ( 44.4km/hr) – and outstanding fuel efficiency. They all boast stability, durability, space, efficiency, luxury, and ease of handling.

Leopard Catamaran boats have a better build than other similar catamaran brands. They also provide a better performance, more comfort, and higher value. With the experience garnered from producing numerous charter boats, plus their active response to customer feedback, Leopard Catamarans has learned to build the kind of boats that people genuinely enjoy sailing.

So, if you are keen to get yourself a Leopard Catamaran, start by determining your budget. Next, look through the various models within the Leopard line, attend boat shows, and you are sure to find a Leopard Catamaran that meets your fancy. To happy sailing!

Owner of CatamaranFreedom.com. A minimalist that has lived in a caravan in Sweden, 35ft Monohull in the Bahamas, and right now in his self-built Van. He just started the next adventure, to circumnavigate the world on a Catamaran!

2 thoughts on “ Are Leopard Catamarans Good? A Complete Review ”

You tube travel sketch would disagree with you 🙄 😒 😑

Which video are you thinking about? Would be interesting to see 🙂

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name and email in this browser for the next time I comment.

Recent Posts

Must-Have Boat Gear for Catamaran Sailors!

Sailing is probably the most gear-intensive activity I've ever done; there are so many decisions to be made about what gear to buy now, for tomorrow, and what to definitely never buy. The gear on...

6 Best Trailerable Trimarans For Bluewater and Coastal Sailing

Having a boat costs a lot of money, even when you are not using it, marina fees, etc. And once it is in the water most sailors never go very far from their "home marina" and sailing will be somewhat...

- Search forums

- Yachting Monthly's Scuttlebutt

You might not want to buy a Leopard catamaran

- Thread starter geem

- Start date 3 Sep 2023

Well-known member

I’m struggling to concentrate..

I can't help pondering on the breaking strain of that thin piece of material..

Chiara’s slave

veshengro said: I can't help pondering on the breaking strain of that thin piece of material.. Click to expand...

I wouldn’t buy a Leopard...she gets her points across very well

Fr J Hackett

Bouba said: I wouldn’t buy a Leopard...she gets her points across very well Click to expand...

Fr J Hackett said: Look it's close to your bed time thoughts like these are going to give you a restless night. Stop looking at the computer go and have a hot milk drink and go to bed. Click to expand...

We went to SA to see the yachts being built (we were visiting SA anyway). The main deterrent for us was that customisation was, effectively, non-existent. The production is geared for charter work, end of story. When you are spending large sums of money on a yacht we, rightly or wrongly, thought customisation should be part of the package. We did not get into the nitty gritty of leaking windows. On the other hand Lightwave were completely gear up for customisation, extra head, deep freeze (in cabin sole), gas fired hot water, 3rd reefing line for main, inner forestay etc - none of which seemed 'out of the ordinary', it was a no brainer. Jonathan

That is Leopard off our final two cat options, then.

It seems boats built for the charter market are frequently a bit short of quality. Though I think I’d rather the hatches leaked than the bulkheads were’t laminated in properly, like another brand of charter catamaran.

Neeves said: We went to SA to see the yachts being built (we were visiting SA anyway). The main deterrent for us was that customisation was, effectively, non-existent. The production is geared for charter work, end of story. When you are spending large sums of money on a yacht we, rightly or wrongly, thought customisation should be part of the package. We did not get into the nitty gritty of leaking windows. On the other hand Lightwave were completely gear up for customisation, extra head, deep freeze (in cabin sole), gas fired hot water, 3rd reefing line for main, inner forestay etc - none of which seemed 'out of the ordinary', it was a no brainer. Jonathan Click to expand...

Active member

I’d still rather deal with leaky windows on a Leopard rather than a failed main bulkhead on a Lagoon !!

It’s a marketing directors worst scenario...a well endowed girl publicly complains about your product

boomerangben

It is interesting in this day and age such issues exist in yacht building given design standards set by governments and so on. It seems that cats have some big challenges for structural engineers which if this thread and perceptions of Lagoons are bourn out with significant data, ie more than a few bulkheads have failed and more than a few Leopards have leaking hatches. Perhaps it’s a matter of quality control or corner cutting. It’s good that people can call out builders like this, but we have no idea if this is a one off or endemic. I hope they can get a successful resolution with the builder, otherwise the second hand value of their investment is going to take a huge hit after all this negative publicity

boomerangben said: It is interesting in this day and age such issues exist in yacht building given design standards set by governments and so on. It seems that cats have some big challenges for structural engineers which if this thread and perceptions of Lagoons are bourn out with significant data, ie more than a few bulkheads have failed and more than a few Leopards have leaking hatches. Perhaps it’s a matter of quality control or corner cutting. It’s good that people can call out builders like this, but we have no idea if this is a one off or endemic. I hope they can get a successful resolution with the builder, otherwise the second hand value of their investment is going to take a huge hit after all this negative publicity Click to expand...

On leaky hatches, she explained clearly the main cause was failing to follow the manufacturer's instructions on installation, not the hatches themselves. Not leveling the mounting flange in the moulding and not installing the fastenings correctly. Both a mixture of poor moulding design, manufacture and quality control. At one point she noted that even the warranty repair crew did not follow the instructions. These hatches are used in their thousands by production builders who I think have fewer issues because their production methods ensure more consistency. The small volume builders rely more on individual fitters than on factory type process control.

The number of leaks they seem to have experienced, in addition to the hatches, is woeful. There's snagging and chasing poor build. Is it a "Friday boat?".

Wandering Star

I delivered a Leopard from Croatia to St Lucia, i wrote about it on here several years ago. Long story short, the hardtop Bimini wanted to go walkabout before we’d even reached Gibraltar, the bolts holding it to the uprights were inside the uprights and effectively inaccessible, had the Bimini gone walkabout so too would the main sheet tackle so I ended up rigging a spanish windlass across from port to starboard to hold it down. The patio style sliding doors kept jumping off their tracks. It was shabbily put together - I certainly wouldn’t buy one for myself even if I could afford to. Sailing performance was crap too. However the trip itself was one of my most enjoyable, great crew - we had a ball.

Leopards are a side line for the builder - they build for Sunsail and I have to assume meet Sunsail's demands. They do, or distributors do - sell them to private buyers. No-one forces anyone to buy a Sunsail yacht (and if its a cat might be branded a Sunsail XYZ). No one forces anyone to buy a Lagoon. Both yachts meet the demands of the charter market, in the same way a HYUNDAI or Opel meets a different demand to a Land Rover Defender. You would not drive a Kia over the Sahara ...... Yachts, and catamarans especially are not cheap - do your home work - it does not cost much to charter one nor go visit the factory. Horses for courses. The faults of yachts are all documented, by now - buyer beware. Jonathan

Other threads that may be of interest

- Irish Rover

- Practical Boat Owner's Reader to Reader

- 29 Aug 2024

Members online

- john_morris_uk

Share this page

- Find or Create a Group

Keyboard Shortcuts

- Leopardcatamaranowners

- previous page

Leopard early 46 bulkhead strenthening

| Hoss Saunders |

| All Messages By This Member Show quoted text <hosso1= > wrote: : : : : |

| Hoss Saunders Show quoted text <hosso1= > wrote: -- : : : : |

| All Messages By This Member Show quoted text <hosso1= > wrote: > wrote: <hosso1= > wrote: -- : , Racing Park, Killarney Gardens : : : : : : : |

| All Messages By This Member Show quoted text <hosso1= > wrote: |

| Hoss Saunders Show quoted text <hosso1= > wrote: |

| Hoss Saunders Show quoted text On Monday, July 26, 2021, 12:27 PM, Ed Koplin <88buynow@...> wrote: <hosso1= > wrote: |

| Hoss Saunders Show quoted text On Monday, July 26, 2021, 12:30 PM, Hoss Saunders via groups.io <hosso1@...> wrote: On Monday, July 26, 2021, 12:27 PM, Ed Koplin <88buynow@...> wrote: <hosso1= > wrote: |

| All Messages By This Member Show quoted text <hosso1= > wrote: > wrote: <hosso1= > wrote: -- : : : : |

| Hoss Saunders Show quoted text <hosso1= > wrote: > wrote: <hosso1= > wrote: -- : : : : |

Verify Delete

Verify repost, report message.

Note: Your email address is included with the abuse report.

Split Topic

The new topic will begin with this message. Subject of the new topic:

- YouTube Videos

- YouTube Channels

- Maritime Dictionary

A password will be e-mailed to you

Reset Password

#142t Does the LEOPARD 45 have BULKHEAD Issues. I'm ALONE on board, am I in TROUBLE? | Sailing Sisu

August 08, 2021 by Sailing Sisu | Language: EN Play Time: 00:16:23 | SAILING YOUTUBERS

With all the commotion going on regarding faulty bulkheads, we decided to check Sisu’s bulkheads. Petro is all alone on board in hurricane season and zone, will it be safe for her to sail to safety should a hurricane approach?

A big shoutout to all our subscribers, you guys rock! And to y’all not yet subscribed, please hit that RED SUBSCRIBE (it’s free) then the BELL (it’s free too) so that you won’t miss our latest releases. AND if you liked what you saw or have some advise to give us, the THUMB and leave a COMMENT (it’s free too!) 🙂

www.YouTube.com/c/SailingSisu Reward us on Patreon to update our equipment: patreon.com/SailingSisu Blog: sailingsisu.blog Facebook: facebook.com/SailingSisu Instagram: instagram.com/SailingSisu Twitter: @SailingSisu. Tumbler: sailingsisu.tumblr.com Flickr: flickr.com/people/SailingSisu Music: epidemicsound.com Leopard Catamarans: leopardcatamarans.com (mention Sailing Sisu and see what happens 😉

Theme Song: written and composed by Ghapi, song name is Sisu. https://www.youtube.com/playlist?list…

We purchased a Leopard 45 Catamaran to sail around the world. Our channel documents our thought and decision making processes with regards to the preparations of getting her kitted out for our needs. We want to visit off the beaten track places and need to prepare for ice bergs, storms, heavy seas, as well as nice tranquil tropical waters… Follow us on our journey, of which we’ve done more than 20 000 miles already. Our wish is that you may hopefully live vicariously through our adventures, or take some valuable information with you that might assist you in your endeavors some day.

#142t Does the LEOPARD 45 have BULKHEAD Issues. I'm ALONE on board, am I in TROUBLE? | Sailing Sisu Locations

Sailing sisu.

Channel Information:

Social media links:, note of recognition for sailing sisu.

At WeBoating.com, we profoundly acknowledge the unwavering dedication that Sailing Sisu and other creators invests in crafting each and every video. Their passion for delivering exceptional content shines through every frame, and it's a labor of love that deserves your attention.

We invite you to watch their captivating videos and actively engage with their content, including their social media links above. Liking, commenting, and sharing their work goes a long way in fueling their creative fire.

We're also inviting you to explore any sponsorships and partnerships highlighted in the video descriptions above or directly in the YouTube . By considering their offerings or purchasing services and items, you not only support Sailing Sisu but also the brands and collaborators they're associated with.

If you have any feedback, corrections, or additional information about the video listed above, please use the comment form below to share your thoughts with us.

Thank you for being a part of our community and supporting the creators we cherish. Your time and support truly matter!

Leave a Reply Cancel Reply

You must be logged in to post a comment.

Sailing Sisu Lastest Videos

#245t WHY does the Leopard Windows DELAMINATE? Sailing Sisu Leopard 45 Catamaran Circumnavigating

#244 Part 2 I-65 over Thorny Path from Bahamas to Puerto Rico | Sailing Sisu Leopard 45 Cat

#243 RECOMMENDED I-65 over Thorny Path from Bahamas to Puerto Rico | Sailing Sisu Leopard 45 Cat

#242 Solo Sail – 1,009nm Thorny Path using 300 liters of Diesel | Sailing Sisu Leopard 45 Catamaran

#241 Solo Sail – Thorny Path brakes the boat | Sailing Sisu Leopard 45 Catamaran Circumnavigating

#240 NOT RECOMMENDED – Solo Sail – The Thorny Path Day 1 | Sailing Sisu Leopard 45 Catamaran

Log in to your account, create an account, forgot password.

Did You Know That We Offer Contract to Closing Services? Click Here to Find Out More.

Need Marine Financing? Apply Here With Our Partner, First Approval Source

- Catamaran Interviews

- Catamaran Reviews

- Buying Advice

- Selling Advice

- Woods Design Advice

- Admiral 38

- Admiral 40

- Admiral 50

- Americat 3014

- Antares 44

- Aquila 44

- Aquila 48 Power Catamaran

- Aventura 37

- Balance 442

- Balance 482

- Balance 526

- Bali 4.0

- Bali 4.1

- Bali 4.2

- Bali 4.3

- Bali 4.4

- Bali 4.5

- Bali 4.6

- Bali 4.8

- Bali 40 Catspace

- Bali 5.4

- Bali Catsmart

- Beneteau Blue II

- Broadblue 346

- Broadblue 38 Prestige

- Broadblue 385

- Broadblue 435

- Broadblue 46

- Rapier 400

- Rapier 550

- Catalac 10M

- Catalac 11M

- Catalac 12M

- Catalac 8M

- Catalac 900

- Catalac 9M

- Catana 381

- Catana 39

- Catana 401

- Catana 40S

- Catana 411

- Catana 42

- Catana 42 S

- Catana 431

- Catana 44

- Catana 471

- Catana 50

- Catana 521

- Catana 531

- Catana 55

- Catana 581

- Catana 65

- Catathai 44

- Chris White

- Chris White 48 Voyager

- Chris White 55

- Condor 40

- Contour 34

- Corsair F28 R

- De Villiers

- Dean 365

- Dean 400

- Dean 440

- Dean 500

- Dix DH550

- Dolphin 380

- Dolphin 460

- Edel 35

- Endeavour 30

- Endeavour 35 Victory

- Endeavour 36

- Endeavour 44

- Endeavour 44 TrawlerCat

- Endeavour 50 Pilothouse Trawler

- Excess 11

- Excess 15

- F-41

- Fastback 43

- Fastcat 445

- Fisher 28

- Fisher 32

- Fortuna 36 Island Spirit

- Fortuna 401 Island Spirit

- Fountaine Pajot

- FP 32 Maldives

- FP 35 Tobago

- FP 36 Mahe

- FP 37 Antigua

- FP 38 Athena

- FP 39 Fidji

- FP 40 Isla

- FP 40 Lavezzi

- FP 40 Lucia

- FP 40 MY

- FP 40 Summerland MY

- FP 41 Lipari

- FP 42 Astrea

- FP 42 Venezia

- FP 43 Belize

- FP 44 Helia

- FP 44 Orana

- FP 45 Elba

- FP 46 Bahia

- FP 46 Casamance

- FP 48 Salina

- FP 50 Saba

- FP 56 Marquises

- FP 57 Sanya

- FP 58 Ipanema

- FP 60 Eleuthera

- FP Saona 47

- Fusion 40

- Gemini 105

- Gemini 3000

- Gemini 3200

- Gemini 3400

- Gemini Freestyle 37

- Gemini Freestyle 399 Power

- Gemini Legacy 35

- Grainger 420 Mystery Cove

- Gunboat 55

- Hirondelle 7M

- HopYacht 30

- Island Packet

- Island Packet Cat 35

- Kennex 420

- Knysna 440

- Knysna 480

- Knysna 500

- Knysna 550

- Lagoon 35

- Lagoon 37 TPI

- Lagoon 380

- Lagoon 39

- Lagoon 40

- Lagoon 400

- Lagoon 410

- Lagoon 42

- Lagoon 42 TPI

- Lagoon 420

- Lagoon 421

- Lagoon 43 PC

- Lagoon 44 Power Cat

- Lagoon 440

- Lagoon 450

- Lagoon 46

- Lagoon 470

- Lagoon 50

- Lagoon 500

- Lagoon 52F

- Lagoon 55

- Lagoon 560

- Lagoon 570

- Lagoon 620

- Lagoon Seventy 8

- Lagoon Sixty 7

- Leeuwin 42

- Leopard 38

- Leopard 39

- Leopard 39 PowerCat

- Leopard 40

- Leopard 42

- Leopard 43

- Leopard 44

- Leopard 45

- Leopard 45 Classic

- Leopard 46

- Leopard 46 Lion PowerCat

- Leopard 47

- Leopard 47 PowerCat

- Leopard 48

- Leopard 50

- Leopard 51 PowerCat

- Leopard 53 PowerCat

- Leopard 58

- Lidgard 73 Executive

- Looping 50

- Maine Cat 30

- Maine Cat 38

- Maine Cat 41

- Manta 40

- Manta 42

- Matrix 450 Vision

- Matrix 760 Silhouette

- Maverick 400

- Maverick 420

- Maverick 440

- Moxie 61

- Nautitech 40

- Nautitech 40 Open

- Nautitech 44 Open

- Nautitech 442

- Nautitech 46 Open

- Nautitech 47

- Nautitech 47 Power

- Nautitech 475

- Nautitech 65

- Neel 45

- Neel 47

- Outremer 40

- Outremer 45

- Outremer 50 Standard

- Outremer 55

- Outremer 5X

- PDQ 32

- PDQ 36

- PDQ 42 Antares

- Privilege 37

- Privilege 39

- Privilege 42

- Privilege 43

- Privilege 435

- Privilege 45

- Privilege 465

- Privilege 48 Transcat

- Privilege 482

- Privilege 495

- Privilege 510

- Privilege 65

- Privilege Serie 5

- Prout 31 Quest

- Prout 33 Quest

- Prout 34 Event

- Prout 35 Snowgoose

- Prout 37 Snowgoose

- Prout 37 Snowgoose Elite

- Prout 38

- Prout 38 Manta

- Prout 39 Escale

- Prout 45

- Prout 46

- Royal Cape 45

- Royal Cape 500 Majestic

- Royal Cape 530 Majestic

- Sailcraft 30 Iroquois

- Sailcraft 32 Comanche

- Sailcraft 35 Cherokee

- Sailcraft 41 Apache

- Sailcraft 44 Apache

- Scape 39

- Wildcat 350

- Seacart 30

- Seawind 1000

- Seawind 1160

- Seawind 1190

- Seawind 1200

- Seawind 1260

- Seawind 1600

- Simpson 48

- Solaris 36 Sunrise

- Solaris 36 Sunstar

- Solaris 42

- St Francis 44

- St Francis 48

- St Francis 50

- Stealth 11.8

- Sunreef 60

- Sunreef 62

- Sunreef 70

- Sunreef 74C

- Sunreef 82 DD

- Sunreef 88 DD

- Switch 51

- Switch 55

- TRT 1200

- Heavenly Twins 26

- Ocean Twins 38

- Vaan R5

- Vision 444

- Voyage 380 Maxim

- Voyage 400 Norseman

- Voyage 430 Norseman

- Voyage 440

- Voyage 450 Cabriolet

- Voyage 47 Mayotte

- Voyage 480

- Voyage 500

- Voyage 580

- Voyage 590

- Kronos 45

- Wharram 38 Tiki

- AMI 320 Renaissance

- Woods 22 Wizard

- Woods 35 Banshee

- Woods 35 Flica

- Woods 36 Scylla

- Woods 36 Vardo

- Woods 38 Transit

- Woods 40 Meander

- Xquisite X5

- Xquisite X5+

Leopard 46 Review: Better than a Lagoon?

- Post author By Richard

- Post date December 7, 2011

- No Comments on Leopard 46 Review: Better than a Lagoon?

Clients often debate about which of the production catamaran brands to purchase. Is there a significant difference between a Fountain-Pajot, Lagoon, and Leopard? After an 11 day delivery of a Leopard 46 from Fort Lauderdale to Cartagena, Colombia and a delivery of a Lagoon 440 in March from Fort Lauderdale to Annapolis , in many respects the Leopard out classed the Lagoon including performance, durability, and comfort. My colleague and super star sailor Kevin Bray lauded the Leopard throughout the delivery. “After working on this boat for 3 months and now sailing her, I can honestly say I like this Leopard 46 design, and there are not a lot of boats that I can say that about,” shared Kevin. In a few areas, I give the edge to Lagoon. Read on to see which.

John Robertson and the late Jerry Caine founded the manufacturer Robertson & Caine in 1991 in Cape Town, South Africa. Initially, the business involved custom mono-hull sailing yacht building. The 70ft maxi, Broomstick, won the Cape to Rio International Yacht Race in 1993 and impressed international racing enthusiasts. This interest enabled the company to be awarded the licence to manufacture the Mumm 36 racer designed by Bruce Farr and attracted the interest of the yacht charter company Tui Marine.

Since 1994 the South African yard has enjoyed a relationship with Tui Marine, owner of charter companies Moorings and Sunsail. R&C has supplied more than 800 Leopard catamarans to Tui Marine. The Leopard historical range includes 38, 39, 40, 42, 43, 44, 45, 46, 47, and 62-foot models by naval architects Gino Morrelli and Pete Melvin or Alexander Simonis and Maarten Voogd. Today, Robertson & Caine is South Africa’s largest boat-building exporter launching on average three boats a week. Cruising World recently awarded their new Leopard 44, their 2012 cruising boat of the year.

First Impressions

In the same way Lagoons are easily identified by their vertical saloon windows, Leopards have distinct steps in front of their windows for deck manoeuvrability. The 46 is sexy to my eye with her aggressive, possibly feline side windows. These windows are paired with the typical fine bows, trampoline centerline forward, and sugar scoop sterns aft. Large, industrial dingy davits leave you feeling safe on the high seas with your tender tightly secured. The helm positioning is like the Lagoon 420 instead of the 440, offset portside. This provides more security though I enjoyed the high positioned, flybridge of the 440 while in close quarters or docking.

Underneath the bridgedeck has above average clearance for offshore performance. There is an escape hatch centerline just below the entranceway. The keels are sacrificial and secured via large diameter horizontal keel bolts. These bolts corrode but are easily maintained if you check on them after each haul. The Yanmar saildrives stick through the bottom next and help Robertson & Caine maximize interior space. Spade rudders are aftmost.

Construction and What To Look For

I heard a story about Moorings whose US sales office is at Harbortown next door to our office here in Dania Beach, Florida. Originally they chartered in the Caribbean both Lagoon and Leopard catamarans. But they found that the Lagoons did not hold up and that the higher quality build of the Leopards maximised their profits. From my comparison in every respect, Leopard makes the choice towards higher quality materials, more sophisticated techniques, or more robust engineering. One thing to look at are the edges on the laminated cabinetry. More often than not Leopard finished out the edges to prevent water intrusion while Lagoon rarely does. It is these kind of small yet important things on yachts that differentiates quality which can withstand the many years of cruising abuse.

On deck the Leopard 46 features watertight compartments port and starboard for storage. Aft of the trampoline is the windlass, water tankage, sail storage, and generator compartments. The generator in its sound proof shield aboard the yacht I delivered was incredibly quiet. For security at the mast, I love Robertson & Caine’s semicircle support on the mast. Like granny bars this helps you stay on the boat in rough conditions offshore. It also is a step to help climb the mast and a rack to coil and tie the bitter end of halyard lines to. The distinctive and functional Leopard glass steps allow you to easily mount the rooftop. While anchored at Staniel Cay, I ignored the “Do Not Dive From Platform” sign and had great fun launching myself from 15-feet in the air and swan diving in between the davits into the beautiful, azure Bahamian waters.

The cockpit aboard the Leopard 46 is incredible and illustrates why people love catamarans. While on a mono-hull you would spend your time cramped in a long narrow cockpit, here you can luxuriously lay out in an incredible number of ergonomic spots. We dined, navigated, and fished from the cockpit. In the Caribbean, we were rarely inside except to sleep, navigate from the nav station, or cook. The stern swim platforms provide easy access to the water and a place to cleanly gut fish.

One feature Lagoon has over Leopard is a lighter interior. While the Leopard is open and light, Lagoon takes this to another level with the vertical, uninhibited windows. Leopard has those steps which block light and visibility from the interior. The woodwork is lighter on Lagoons as well which often draws a quiet preference from clients.

Catamaran layouts are mostly the same these days. Sure some cats have galleys down, but by and large especially on larger cats, the galley up arrangement is standard. I sailed to Colombia aboard the owner version of the Leopard 46 where the starboard hull has a large master head forward and light and airy master berth aft. This owner suite makes a big difference for clients who are dislike the dark, closed in feel of the 2 head, 2 stateroom charter hull.

One of my biggest complaints during my earlier delivery of the Lagoon 440 to Annapolis was the low and uncomfortable nav station seat. I was pleased to experience on the Leopard a proper height and ergonomical seat with multiple seating options, likewise for the exterior helm. It did not hurt that the Leopard owner had made some savvy upholstery decisions to heighten the comfort factor.

The engines are Volvo D55, Yanmar 4JH3E, or Yanmar’s latest saildrives, the 54HP Yanmar 4JH4’s. Our 4JH4 ran smoothly throughout our trip. The only catch was an unusual buzzing sound. We finally figured out that this happened when when boat speed outpaced engine speed. The saildrives were telling us “what the hell are you doing? Either ramp up the RPM’s or turn me off.” We motored at 7 to 8 knots at 2,000 RPM’s burning about .9 gal/hour of diesel.

I prefer the Leopard’s engine room arrangement. While overlaying the engine rooms on Lagoons are plywood laminated levels, the Leopard has open compartments with a single removable glass board across. Storage for gerry cans is available behind the engines. This space fits 3 easy and maybe a fourth can. We had a little trouble with a leaky gas jug which would have been dangerous if the compartment was not so well ventilated.

During the delivery I had some of the best catamaran sailing ever I have experienced. The smooth motion and minimal slapping even in 10-foot seas and a line squall was the best takeaway from the delivery. Through the windward passage and most of the Caribbean passage, we had 10 to 20 knots of north east wind and following seas. When light we put up the gennaker for a day and a half and made 6 to 7 knots in 5 to 15 knots downwind. As the wind picked up, we put out the jib and main and made 7 or even 8 knots consistently. Our last night in somewhat squally conditions we hit a very unsafe 12 knots before blowing the jib. Upwind we could sail at a reasonable clip of 6 knots up to 60 degrees off apparent wind. Otherwise as we were in delivery mode, we kicked on the iron genny, blew the sails, and motored at 7+ knots.

The premier you pay for a Leopard versus a Lagoon is justified, and for offshore sailing, I would recommend the Leopard. The softer offshore performance, high quality materials, and navigation station comfort give the Leopard my edge. The Lagoon has better interior space, visibility, and airiness. Expect to pay around $600k versus $500k for a late model Leopard 46 compared to an equivalent Lagoon 440.

- Tags Catamaran Reviews

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

- New Sailboats

- Sailboats 21-30ft

- Sailboats 31-35ft

- Sailboats 36-40ft

- Sailboats Over 40ft

- Sailboats Under 21feet

- used_sailboats

- Apps and Computer Programs

- Communications

- Fishfinders

- Handheld Electronics

- Plotters MFDS Rradar

- Wind, Speed & Depth Instruments

- Anchoring Mooring

- Running Rigging

- Sails Canvas

- Standing Rigging

- Diesel Engines

- Off Grid Energy

- Cleaning Waxing

- DIY Projects

- Repair, Tools & Materials

- Spare Parts

- Tools & Gadgets

- Cabin Comfort

- Ventilation

- Footwear Apparel

- Foul Weather Gear

- Mailport & PS Advisor

- Inside Practical Sailor Blog

- Activate My Web Access

- Reset Password

- Customer Service

- Free Newsletter

The PDQ 32 Cruising Cat Used Boat Review

Dufour 44 Used Boat Review

Blue Jacket 40 Used Boat Review

Catalina 270 vs. The Beneteau First 265 Used Boat Match-Up

How to Create a Bullet-Proof VHF/SSB Backup

Tips From A First “Sail” on the ICW

Tillerpilot Tips and Safety Cautions

Best Crimpers and Strippers for Fixing Marine Electrical Connectors

Revive Your Mast Like a Pro

Solving the Dodger Dilemma

Polyester vs. Nylon Rode

Getting the Most Out of Older Sails

Sailing Triteia: Budget Bluewater Cruising

How To Keep Pipe Fittings Dry: Sealant and Teflon Tape Tests

Fuel Lift Pump: Easy DIY Diesel Fuel System Diagnostic and Repair

Propane Leak: How to Detect, Locate and Fix

Why Choose the Wharram Design?

Winterizing: Make It Easy With Checklists

Stopping Holding-tank Odors

Giving Bugs the Big Goodbye

Galley Gadgets for the Cruising Sailor

The Rain Catcher’s Guide

Sailing Gear for Kids

What’s the Best Sunscreen?

UV Clothing: Is It Worth the Hype?

Preparing Yourself for Solo Sailing

R. Tucker Thompson Tall Ship Youth Voyage

On Watch: This 60-Year-Old Hinckley Pilot 35 is Also a Working…

On Watch: America’s Cup

On Watch: All Eyes on Europe Sail Racing

Dear Readers

- Sailboat Reviews

Big Cat Concerns

D avid Shih has quite a story to tell. The boat of his dreams brought on a nightmare of repair work—and YouTube fame. Shih isn’t alone, at least in the nightmare part. Shih’s story is one of many about bulkhead problems on the Lagoon 450 catamaran that have gotten widespread attention online. The attention persuaded Lagoon, a brand owned by Beneteau, a French public limited corporation (SA) that is one of the world’s most famous boatbuilders, to take action.

At first Shih noticed the interior joinery had shifted. Then the rigging got loose. Eventually he worked up the courage to look in the corners of the engine room, behind lockers, and even removed some trim. Cracks were everywhere—in bulkheads, in stringers, and in floors.

The most obvious failure was in the main bulkhead, the massive lateral bulkhead located near the mast that ties both hulls and the main cabin together. Shaped like a flattened upside-down U, this is one of the most important structural elements in a catamaran, preventing the hulls from bowing outward under rigging loads, or twisting excessively in a cross sea.

Shih was nearly certain that the trouble he found wasn’t caused by some prior damage. He noticed parts of the main bulkhead that were only partially bonded to the hull structures. He found bulkheads and stringers that were simply glued rather than taped and glassed into place. It was the sort of construction that one sees in a travel trailer, but doesn’t belong in offshore boat construction. His suspicions were confirmed when he got in contact with other owners whose boats had no history of collision or grounding, or conditions that a sailor would regard as extreme. They, too, discovered warped and fractured main bulkheads.

According to Shih, at first, there was hesitancy among the owners to talk openly about the problems. Reveal flaws in your boat and resale value can plummet. In the case of a large catamaran, a serious flaw could mean tens of thousands of dollars in lost value.

Not surprisingly, even owners of other Lagoon models that showed no signs of weakness or damage, objected to open discussion of the bulkheads in the 450 model. They feared their boats would be devalued by association. So the problem, which first came to light in 2020, did not immediately get widespread attention.

When dozens of owners voiced their concerns on YouTube, Facebook, or other social media outlets, Lagoon’s Brand Director Thomas Gailly took heed, and the company put together a Lagoon 450 Support page ( www.cata-lagoon.com/en/lagoon-450-support ) addressing their concerns. They also prepared a repair kit to stiffen the main bulkhead, and published guidance on how to install the repair kit. It was a major repair that required removing a great deal of interior trim.

REASONABLE EXPECTATIONS

When buying a new fiberglass boat, it is reasonable for an owner to assume the basic structural integrity—hull, deck, and bulkheads—will remain intact for about 30 years, assuming we don’t expose it to extreme conditions that will overstress the boat (a hard grounding, for example). Lagoon’s response to the bulkhead debacle suggests that abuse as defined in the owners manual may be a cause for some of the failures.

The following are some of Lagoon’s examples of “abnormal” use of the boat, which according to Lagoon, could overstress the hull and eventually lead to the sort of damage that owners have been reporting in the Lagoon 450.

• Sailing with more sail area than allowed on the Owner’s Manual sailing advice.

• Powering against sea and wind for a long time at 30-degrees off the true wind.

• Sailing in very shallow waters to a point where waves could end up in occasional groundings.

• Anchoring in very shallow waters to a point where waves could end up in occasional groundings.

• Grounding.

• Tightening the rig out of the mast manufacturer specification.

• Improper haul out and storage.

Yes, catamarans flex more than monohulls. Beating into seas generates powerful torque on the hull. But cheap plywood with a low thickness to cord ratio and no edge flange is not the way to build the main bulkhead on a 45-foot catamaran, in our view.

In most of the cases we reviewed it seems very unlikely that the failures were due to extraordinary circumstances—a bone jarring grounding, hurricane damage, or being dropped from a Travelift, etc. By all appearance, it seems the normal stress and strain that a boat encounters at sea was simply too much for some of these boats. It is worth noting that this is the sort of stress and strain that Lagoon’s other models seem to shrug off without significant damage.

THE SCOPE OF THE PROBLEM

Because of a natural tendency among owners to handle things quietly, no one is quite sure how widespread the problem is. According to Lagoon’s website, about 1,100 hulls were built from 2010 to early 2020 when the line was discontinued. As of August 2021, Lagoon said it had been contacted by 155 owners, and that 50 boats with bulkhead-related problems were being repaired or had been already repaired. Although we requested them, updated numbers were not provided to PS at the time of this publication.

The repaired boats all showed the same bulkhead vulnerabilities, and whether the weakness became apparent often depended on age, construction details, and how the boat was sailed. No sunk or abandoned boats have been blamed on these failures. Lagoon reinforced the passageway beam in models built after 2012, but admitted no flaws, describing the change as a typical in a boat model’s production cycle.

POSSIBLE CAUSES

It appears several causes are at work. Ruling out extreme events, the failures we observed are likely related to under-engineering, material selection, or quality control at the factory.

Poor bonding. Many of the bulkheads pulled away from the hull or adjacent structure without signs of wood failure. It appears the glue did not bond properly. This suggests a lack of surface preparation before bonding.

Weak material. Several cases of buckling bulkheads that we’ve reviewed suggest the use of materials that were not capable of withstanding prolonged ocean sailing loads. In short, the bulkhead plywood laminate was too weak.

Anticipating the loads on a main bulkhead of a cruising catamaran is not rocket science. The loads can be simulated by computer and the required strength to withstand such loads has been published in engineering manuals for more than 100 years.

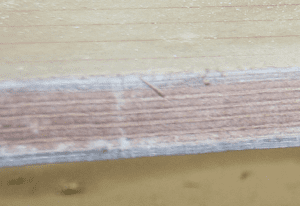

Based on what we’ve been able to discern from photos taken by owners, the plywood used in the bulkheads of the Lagoon 450 appears to be a more economical variety, not the high-quality, high-density, high-strength marine grade plywood that would be preferable in a structural bulkhead.

As for Lagoon’s repair plan, sandwiching the weakened bulkhead section with new plywood as a repair— initially suggested by Lagoon—strikes us as a band-aid solution that does not solve the underlying problem. Without further FEA analysis, any underlying engineering problems are speculative.

LAGOON’S RESPONSE

Eventually, Lagoon mounted a strong response. They offered to inspect the forward bulkhead (only one of the common failure locations) at no cost if the boat was brought to an authorized dealer or service center. If cracked, the bulkhead would be repaired by sandwiching the fractured section in what amounts to a mechanical splint. Additional plywood would stiffen and straighten the bowed or broken structure.

If the boat is still covered by the three-year warranty, the full cost of the repair will be covered. If the boat is out of warranty, only the labor will be covered by the repair. The repair is guaranteed for one year. Lagoon says it is responding to every owner, even those whose boat’s do not show signs of bulkhead damage.

Lagoon had the original designer perform finite element analysis on the main beam design only. According to Lagoon, this analysis found that this structure had an adequate safety factor to withstand predicted loads. The analysis assumes there are no factory flaws. Notably, it did not predict the failures experienced by owners, nor did it describe the impact of a bulkhead failure on surrounding structures.

Other bulkheads and structures were not included in this finite element analysis, and a hull bulkhead does not function in isolation. If parts of the design were either under-engineered or poorly executed, a subsequent FEA would help identify these weak points.

Lagoon owners said they were told that because the boat must flex, some “settling” will occur. It is true that flexing can be expected, but based on what we’ve observed in the damaged boats, Lagoon’s bulkhead is a brittle design that is bound to crack. A flexible structure is not a weak structure, but one that can absorb loads without cracking.

Lagoon contends that the design itself is not flawed. Among other things, they point to their long history in the demanding charter industry as evidence of their robust specifications.

How concerned should 450 owners and prospective buyers be? Designed for charter use, these boats have more miles under them than any other cruising cat of similar size. But if you are buying one, have the surveyor crawl in and inspect every corner. Remove the covers and inspect the forward bulkheads. If they have been repaired, that’s probably good. Owners who see any sign of over-stress or suspect a weakness at the bulkhead should contact Lagoon.

Lagoon’s long history in the charter trade is proof that the company knows how to build boats that can handle abuse. And the company appears to be making an earnest effort to keep owners happy.

The Lagoon 450 has a lot going for it in terms of easy handling and comfort. However, sound engineering and quality control during construction should always take priority over cosmetics. This becomes especially important as the market demands faster, lighter boats (see “ Multihull Madness ,” March 2017).

Favoring quality construction over creature comforts is never a mistake, and sometimes that means buying a smaller boat, or an older, well-maintained one built to a higher standard.

I n 2006, PS editor Darrell Nicholson was invited by the South African government to tour the plants of several big-name multihull boatbuilders, including Robertson and Caine, Voyage, Admiral, and Two Oceans. Nicholson’s photos taken during tour help illustrate the details of catamaran construction relevant to the Lagoon 450. Writer Nigel Calder describes a more recent visit in ProBoat magazine ( www.proboat.com/2019/07/south-african-boatbuilders-revisited/ ).

1. Bulkheads on a Moorings charterboat are bonded in place before the interior modules are installed. Arrows indicate hot spots where load is concentrated.

2. A partial bulkhead is hand-laminated on the floor at a South African builder. Loads can concentrate at corners in the bulkhead.

3. An interior view of a catamaran under construction shows where the bulkhead has been bonded in place with some tabbing.

4. Both plywood and end-grain balsa core stiffen this main bulkhead which shows a desirable, low-resin matrix in the fiberglass laminate.

Editors note: The following excerpt is from the website that Lagoon set up to address questions about bulkhead failures on the Lagoon 450 ( www.cata-lagoon.com/en/lagoon-450-support ) .

F irst of all, we want to reassure every owner of a Lagoon 450: we do guarantee you that safety and navigability of your boat are preserved whatever the state of your forward bulkhead be.

This guarantee is based on the results of the study we undertook in March 2021, after we realized that there were several Lagoon 450 affected by a forward bulkhead issue. We actually started analyzing the cases reported to us, with some new calculations based on latest available tools, to understand causes and potential impacts of deformed or broken forward bulkhead.

To ensure the reliability of this Finite Element Analysis, we asked VPLP, one of the most renowned international team of naval architects and designers, to review our calculations and results, which they did. They reached the same conclusions as us: there is no safety issue when navigating with a broken or deformed bulkhead. Potential damages on forward bulkhead could not lead to neither dismasting nor any risk for the crew.

How did we come to this conclusion? The forward bulkhead is located in front of the saloon area and is divided into two main areas with different roles:

• The most important one is the central area which withstands 100% of mast compression. This area is stiff and solid. Only this part of the bulkhead has these functions. It cannot be affected by a bulkhead deformation.

• The side parts of the front bulkhead support most of the sea twist effects causing, in a fair number of boats, buckling on its door side. This side part is less rigid to be able to react and guarantee a certain flexibility to the structure of the boat.

LAGOON 450 BULKHEAD

A bulkhead is also present in the aft of the boat. This is much less stressed, and it is also rather flexible so it can evolve through navigation time, like many other parts of the boat.

As you may know, at the dock, the mast compression is at least around 9 tons for Lagoon 450. When sailing, this compression increases. So, for the mast to come out of its mast foot would require that the whole boat flex above overall limit of materials: basically, it would mean that the boat breaks apart which has never been the case on cruising catamaran history.

Consequently, we can reassure you that forward bulkhead issue is not a safety issue. It still may become unpleasant if the reinforcement is made late, since bent or buckling bulkhead will only transfer the stress elsewhere.

Flexibility is inherent to the boat’s construction: reinforcing, straightening up or repairing the sides of the bulkhead will still contribute to preserve it and to get the most from your boat, this is why we recommend doing so. Reinforcement, however, will not (and should not), completely remove the flex, as wear naturally comes from boats’ use, just as flexibility: it is and will remain normal to make layout adjustments over time.

RELATED ARTICLES MORE FROM AUTHOR

Designing a Dump Line for the Multihull Mainsheet

Multihull Capsize Risk Check

Multihull Madness

Leave a reply cancel reply.

Log in to leave a comment

Latest Videos