Please verify you are a human

Access to this page has been denied because we believe you are using automation tools to browse the website.

This may happen as a result of the following:

- Javascript is disabled or blocked by an extension (ad blockers for example)

- Your browser does not support cookies

Please make sure that Javascript and cookies are enabled on your browser and that you are not blocking them from loading.

Reference ID: 7564bb56-7b0d-11ef-84a6-b9366d5a09da

Powered by PerimeterX , Inc.

- FREE SHIPPING on orders over $100

- Account details

- Payment methods

- Lost password

- Privacy Policy

- Shipping Policy

- Return Policy

WORLDS FINEST

Discount prices.

Find the right anode

At the right price..

- Engine Anodes

- Propeller Anodes

- Hull Anodes

- Shaft Anodes

Why shop with us?

Quality assurance, free shipping, choose the right anode:.

Our SeaShield Marine brand anodes offer excellent protection from galvanic corrosion for your metal hull boats. We carry a wide variety sacrificial anode plates and hull zincs.

- Rudder Anodes

Rudder and trim tab anodes are a crucial part of any boater’s regular maintenance schedule. Our domed shaped rudder zincs offer superior protection with minimal drag.

Our sacrificial zinc & aluminum anodes for engines and on-board motors protect your boat’s most critical components. Our engine anodes protect your boat and protect your investment.

Stern Drive Anodes

Stern drive anodes protect your Mercruiser engines from galvanic corrosion. Our selection of stern drive anodes & kits are designed to offer excellent protection no matter the water type.

Shaft anodes protect your propeller shaft from galvanic corrosion and should be checked frequently. Our unmatched quality allows for easy underwater installation. We offer a variety of zinc & aluminum shaft anode collar sizes to meet any need.

Propeller nut anodes protect your boat’s prop & the nuts that keep the propeller attached to the boat. Our wide selection of prop nut anodes in zinc & aluminum is sure to meet your needs.

Try our anode selection tool:

Which type of metal are you protecting?

What type of water will your boat be in?

- Fresh Water (Clean)

- Fresh Water (Polluted)

- Brackish Water

Type of anode we suggest for your boat:

Free shipping on orders over $100, featured products.

New Products

Made In The USA

Welcome to Anode Shack, the internet’s trusted name for marine corrosion control products and home of the World’s Finest Zinc Anodes.

Made in the USA, our sacrificial anodes boast unmatched quality and ingenuity. All our Zinc Anodes are made to MIL-SPEC standards MIL-A-18001 and our Aluminum Anodes are pressure die-cast and engineered to MIL-A-24779 ensuring longevity and precision.

We carry Zinc Anodes, Aluminum Anodes, and magnesium anodes for any of your corrosion protection needs for Boats, Yachts, commercial vessels, and all types of pleasure crafts.

We’d like to hear from you.

- Sterndrive Anodes

- Saildrive Anodes

- Bow Thruster Anodes

- Commercial Anodes

- Industrial Anodes

- Shopping cart 0 You have no items in your shopping cart.

- Check Order Status

- Inboard Boat Props

- Outboard Boat Props

- Sterndrive Props

- PWC Impellers

- Ski/Wake Props

- Authentic Volvo Duo Props

- Propeller Pullers

- Propeller Guides

- Brass cutless bearings

- Non metallic bearings

- Duramax flanged bearing

- Stave bearings

- Shaft Zinc Anodes

- Rudder Zinc Anodes

- Plate Zinc Anodes

- Shaft Nut Zincs

- Stainless Prop Shafts

- Shaft Seals

- Marine Shaft Logs

- Shaft Packing Boxes

- Shaft Accessories

- Deck Hardware

- Drivetrain Hardware

- Marine Exhaust Fittings

- Hose and Clamps

- Steering Hardware

- Marine Valves

- Plumbing Fittings

- Prop Shafting Accessories

- Marine Strainers

- Miscellaneous Hardware

Zimar Plate Zinc Anodes set the standard when it comes to cathodic protection. Zimar plate marine zinc anodes meet all standards set forth by Mil-Spec A-18001K, Mil-Spec A-18001A, and Mil-Spec A-18001. Zimar plate boat zincs are individually hand poured to assure the highest possible zinc concentration and lowest amount of porosity. We carry the entire line of drilled and undrilled bolt on zinc plates, as well as weld on plates and round plates. Order your zinc anodes today and save!

- Drilled Bolt On

- Undrilled Bolt On

- Round Plate

- Cutlass Bearings

- Shafts & Seals

- Boat Hardware

- 1-800-454-6960

- 1-321-978-0253

- 1-954-444-6259

- [email protected]

- DeepBlueYacht

- Contact Us With Questions

- Shipping and Return Policy

- Privacy Policy

- Conditions of Use

- Company Overview

- Engine_Fuel & Props

- Engine Accessories

Zincs & Anodes

Sierra 18-6241 Trim Tab Anode Replaces41107-ZW1-003ZA

Sierra 18-6241 Magnesium Trim Tab Anode for Mercruiser, Mercury Sierra high quality aftermarket marine parts are manufactured to meet or exceed OEM requirements. Magnesium trim tab anodes should be used in fresh water only and with aluminum props...

Lenco Sacrificial Anodes

Lenco Sacrificial Anodes Package of 2. Mounting screw included.

Sierra 23-6400 Anode For Kohler & Westerbeke

Sierra 23-6400 Anode For Kohler & Westerbeke Sierra high quality parts are designed to meet OEM specifications. Interchangeable with: Kohler 260085 Westerbeke 11885

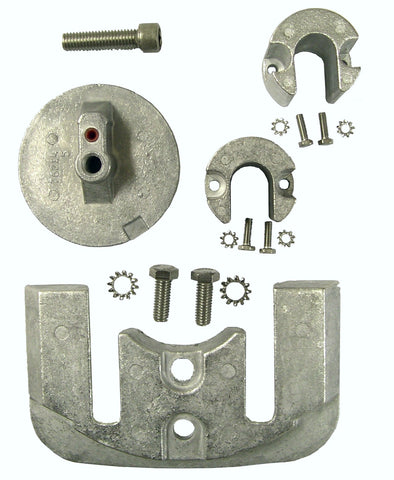

Sierra 18-6158Z Alpha 1 Gen II Anode Kit (Zinc)

Sierra 18-6158Z Mercruiser Alpha 1 Gen II Anode Kit (Zinc) Sierra replacement anode kit for use with Mercruiser Alpha One Gen II drives. The anodes found in this kit are constructed of zinc and should be used in saltwater applications only. Sierra...

Tecnoseal Anode Kit w/Hardware - Yamaha 200-300HP Hi-Performance - Zinc

Yamaha 200-300HP Anode Kit - Hi-PerformanceContents:(1) 01112(1) 01145Material: ZincPackaging: PolybagHardware: Included Specifications:Material: ZincBox Dimensions: 3"H x 6"W x 8"L WT: 3.5 lbsUPC: 8059617818944Quick Guide (pdf)Owner's...

Tecnoseal Anode Kit w/Hardware - Mercury Alpha 1 Gen 2 - Magnesium

Mercury Alpha 1 Gen 2 Anode KitContents:(1) 00806BISMG(1) 00814MG(1) 00819MG(2) 00817MG(1) 00820MGMaterial: MagnesiumPackaging: PolybagHardware: Included Specifications:Material: MagnesiumBox Dimensions: 3"H x 8"W x 8"L WT: 1.5 lbsUPC:...

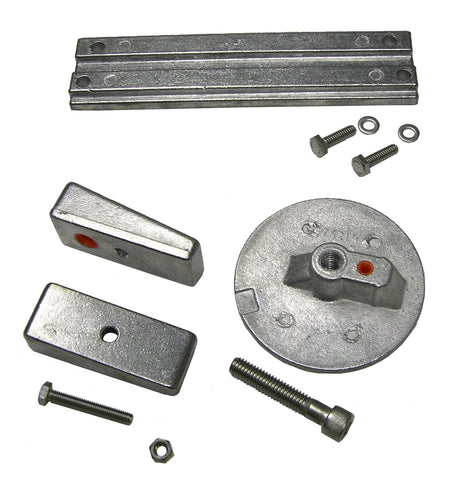

Aluminum Anode Kit, Bravo 3 2003 & Up, Quicksilver 97-888761Q04

Aluminum Anode Kit, Bravo 3 2003 & Up, Mercury - Mercruiser 97-888761Q04 Aluminum anodes for use in saltwater or freshwater This is a complete anode kit to replace all factory installed anodes found on the drive unit. Fits 2003 and newer Bravo III...

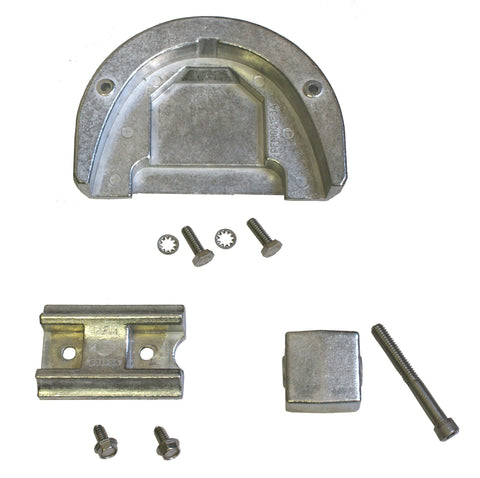

Tecnoseal Anode Kit w/Hardware - Volvo SX - Zinc

Volvo SX Anode KitContents:(1) 00718(1) 00726Material: ZincPackaging: PolybagHardware: Included Specifications:Material: ZincBox Dimensions: 3"H x 4"W x 6"L WT: 4.6 lbsUPC: 8033837068853Quick Guide (pdf)Owner's Manual (pdf)

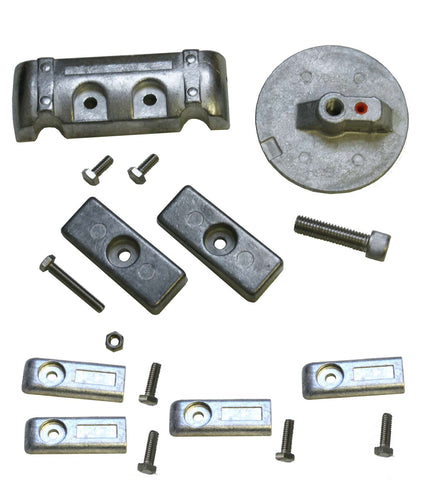

Tecnoseal Anode Kit w/Hardware - Mercury Bravo 2-3 - Magnesium

Mercury Bravo 2-3 Anode KitContents:(1) 00815MG(1) 00820MG(2) 00818MGMaterial: MagnesiumPackaging: PolybagHardware: Included Specifications:Material: MagnesiumBox Dimensions: 3"H x 7"W x 8"L WT: 1.3 lbsUPC: 8059617819392Quick Guide...

Aluminum Anode Kit for Bravo II & Bravo III, Quicksilver 888761Q03

Aluminum Anode Kit for Bravo II & Bravo III, Mercury - Mercruiser 888761Q03 Aluminum Anodes for use in saltwater or freshwater This is a complete anode kit to replace all factory installed anodes found on the drive unit. Fits: Bravo II 1988 and...

Mercury - Mercruiser 822777A-2 Anode Trim Tab (Mag)

Mercury - Mercruiser 822777A-2 Anode Trim Tab (Mag) Magnesium For freshwater use only Do not use in saltwater applications Fits most Mercury/Mariner 35 hp and above, Force 90/120 (1995 and newer), and all Mercury Mercruiser engines.

Sierra 18-6158A Alpha 1 Gen II Anode Kit Replaces 888756Q03

Sierra 18-6158A Alpha One Gen II Aluminum Anode Kit Sierra quality replacement anode kit for use with Mercruiser Alpha One Gen II drives. The anodes in this kit are constructed of aluminum and can be used in brackish, fresh, or salt water applications...

Tecnoseal Anode Kit w/Hardware - Mercury Alpha 1 Gen 2 - Zinc

Mercury Alpha 1 Gen 2 Anode KitContents:(1) 00806BIS(1) 00814(1) 00819(2) 00817(1) 00820Material: ZincPackaging: PolybagHardware: Included Specifications:Material: ZincBox Dimensions: 3"H x 8"W x 9"L WT: 5.5 lbsUPC: 8033837068631Quick...

Sierra 18-6011A Aluminum Anode

Sierra 18-6011A Aluminum Anode Sierra replacement aluminum anode. Aluminum anodes are recommended for boats in brackish water, or if a boat is used in both fresh and salt water environments. Fits: Most Mercury/Mariner O/B's 35hp & above and...

Sierra 18-6158M Alpha 1 Gen II Anode Kit Replaces 888755Q03

Sierra 18-6158M Alpha 1 Gen II Magnesium Anode Kit Sierra quality replacement magnesium anode kit for use with Mercruiser Alpha One Gen II drives. The anodes in this kit are constructed of magnesium and should only be used in freshwater applications...

Tecnoseal Anode Kit w/Hardware - Mercury Alpha 1 Gen 2 - Aluminum

Mercury Alpha 1 Gen 2 Anode KitContents:(1) 00806BISAL(1) 00814AL(1) 00819AL(2) 00817AL(1) 00820ALMaterial: AluminumPackaging: PolybagHardware: Included Specifications:Material: AluminumBox Dimensions: 3"H x 7"W x 8"L WT: 2.2 lbsUPC:...

Tecnoseal Anode Kit w/Hardware - Volvo SX - Magnesium

Volvo SX Anode KitContents:(1) 00718MG(1) 00726MGMaterial: MagnesiumPackaging: PolybagHardware: Included Specifications:Material: MagnesiumBox Dimensions: 2"H x 6"W x 8"L WT: 1.3 lbsUPC: 8059617815479Quick Guide (pdf)Owner's Manual (pdf)

Anode Kit Bravo 3 2003 & Up Magnesiu, Quicksilver 888760Q04

Anode Kit Bravo 3 2003 & Up Magnesiu, Mercury - Mercruiser 888760Q04. SS from 888760q02

Sierra 18-6011 Anode Replaces 41107-ZW1-003ZA

Sierra 18-6011 Zinc Anode Sierra high-quality engine parts are designed to meet OEM specifications. Constructed of zinc. Fits most Mercury/Mariner O/B's 35 HP & above and all Mercruiser engines except Bravo Use with: 18-6245 Anode Mounting...

Sierra 18-6024 Anode

Sierra 18-6024 OMC Zinc Gearcase Anode Sierra replacement anode. Interchangeable with: GLM 12776 Johnson/Evinrude Outboard 393023 436745 OMC Stern Drive 393023 Fits: 1982 - 1987 Gearcase Zinc is for saltwater...

Boat Zincs and Anodes

An essential part on every vessel, zinc anodes for boats are installed to protect underwater metal components, such as a bronze propeller or metal struts, from galvanic corrosion. Galvanic Corrosion occurs when two dissimilar metals are physically or electronically connected and immersed in water. Without any form of protection, galvanic corrosion will cause underwater metals to corrode and waste away. When sacrificial anodes, commonly referred to as zincs, are added to the equation, they will corrode away instead, leaving your metal components intact.

At Wholesale Marine, you'll find zinc anodes, magnesium anodes, and aluminum anodes. Zinc anodes have been used for years and are recommended for saltwater applications. For boats in freshwater, magnesium anodes provide excellent protection, especially for underwater aluminum parts. For boaters who plan to be in brackish water, aluminum anodes are the way to go. Aluminum alloy anodes have become more popular over the years as they have a longer lifespan and provide protection in both fresh and saltwater.

Boat zincs and anodes should disintegrate over time. After a year, even if your zinc anode seems to still be in great shape, it should be replaced as it may contain impurities or have a bad connection. Once your anode is about half done, it's time to replace it (usually every year). At Wholesale Marine, we stock a full line of zinc anodes for boats including engine anodes, prop shaft anodes, anode kits, rudder anodes, and more. In addition, our anode kits make shopping fast and easy.

If you're unsure which option from Wholesale Marine’s selection of zinc anodes for boats is the right choice for you, give us a call! Our call center is available Monday-Friday, 9 AM to 4 PM EST at 1-877-388-2628. Don't forget to ask about our Captain’s Club Rewards Program to learn how you can save on future purchases. We offer same-day shipping on all in stock items, and free shipping on orders over $99.

Subscribe to our Newsletter

Get the latest updates on new products and upcoming sales

Oops, something went wrong. Please try again.

You are now logged in!

What are Zincs on a boat?

Home » What are Zincs on a boat?

Galvanic Corrosion is the problem

When you have two different metals physically connected in seawater electrical current flows between them, essentially turning them into a battery. For that current to exist, one of the metals has to physically give up pieces of itself(metal ions) to create the electrons and feed the current. This process of metal deterioration through electrical activity is known as Galvanic Corrosion. Whether it’s your propeller(bronze or aluminum),or the metals on your prop shaft, rudders, outboard and sterndrives, Galvanic Corrosion can cause major and expensive damage if not controlled.

Sacrificial Anodes (Zincs) stop Galvanic Corrosion

To stop Galvanic Corrosion from destroying your underwater metals you would have to disrupt the process of your boats metals sacrificing themselves to the electrical current. The solution is to add a third metal into the equation, one that sacrifices itself to protect your precious underwater metals, that’s where Sacrificial Anodes come in. Sacrificial Anodes are metals that are quicker to give up pieces of themselves in order to protect your underwater metals, and are most commonly made from Zinc, as it is the best alloy for protecting boats in seawater – hence, boaters refer to Sacrificial Anodes as Zincs. We can’t stress enough how the proper installation and maintenance of your zincs is essential to the protection of your underwater metals – leaving depleted anodes to protect your boat, or even worse, not having any at all will only assure disaster.

How much Zinc to use

There are general rules of thumb when using zinc anodes to protect underwater metals, some say 1 to 2% anode coverage to surface area being protected. However, there are a lot of variables that factor into the effectiveness of your zinc anodes, salinity, temperature, pollution levels, stray current, and water flow play a big part in the depletion of your anodes. Usually, diligent monitoring of your sacrificial anodes through trial and error will let you know the right amount of zinc to use.

Beware of Over Zincing

Beware of using too much zinc. If you use too much zinc the anode will develop a crust, get fouled and stop working. Too much zinc may also cause over protection. Over protection on an aluminum hull or outdrive can also be destructive. Over protecting an aluminum hull can lead to Cathodic Disbondment, where the destruction of adhesion of antifouling paint may occur due to a cathodic reaction.

Installing Zinc Anodes Properly

Sacrificial anodes cannot be put just anywhere. There are some that believe you can mount a sacrificial anode anywhere or even attach it to a string and hang it over the side – They’re wrong! The further a zinc is from the metal it’s supposed to protect, the less effective it becomes. For a zinc anode to be effective you need clean metal-to-metal contact – either by mounting the zinc directly to the metal being protected or by connecting the two with a wire. When mounting a zinc directly make sure the surface is clean before mounting the anode to assure good electrical contact. A hanging anode can provide protection ONLY if it is connected by a wire to the metal being protected. Do not paint your zincs. Bottom paint on a zinc anode will smother it so it cannot perform its duty, rendering it useless.

When to replace your zinc anodes

Salinity, temperature, pollution levels, stray current, water flow and other environmental variables have a major effect on the life of your zinc anodes, so it would be difficult to give a specific time frame. A good rule of thumb and our recommendation is to replace your zincs when they’ve depleted 50%. This assures you optimal performance.

Quality matters.

Make sure you’re protecting your investment by using high-quality anodes – use MIL-SPEC Standards. The MIL-A-18001 Zinc and MIL-A-24779 Aluminum alloys are the preferred choice of the US Military (owners of the Worlds largest Naval fleet) and you shouldn’t use anything less on your craft. At Sea Shield Marine we make the Highest-Quality sacrificial anodes, all of our anodes are made in the USA to MIL-SPEC Standards, are pressure die cast for better density and longer life, and are always designed for reliable performance and easy installation.

FACT: Sea Shield Marine was the first company to introduce MIL-SPEC Standard anodes to the Pleasure Craft Industry (learn our story)

Know your Zincs

Propellers normally use a zinc collar anode for protection, either limited clearance or streamlined collars are preferred and mount to the shaft forward or rear of the propeller. Seashieldmarine.com/Streamline_Collars Seashieldmarine.com/Shaft_Anode_LineCutter Outboard propellers use either a zinc ring or prop nut anode for protection. Seashieldmarine.com/Prop_Nuts

Rudders and Trim Tab

Rudders and Trim Tabs are both protected with similar rudder button style anodes. Rudder Button anodes have a low profile dome shape and are streamlined to minimize drag and turbulence. Seashieldmarine.com/Rudder_Trim_Tab_Anodes

Hull Plates

Boats with bonded electrical systems are usually fitted with one or more zinc plates that are bolted to the hull. The zinc plates, typically referred to as a Divers Dream Plate, are mounted using bolts that connect to electrical cables on the bonding circuit. Zinc plate anodes are also used on metal boats to protect the hull and need to be carefully monitored.

FACT: Sea Shield Marine invented and perfected the Divers Dream Plate and it’s one of our crowning achievements. Seashieldmarine.com/Bolt_On_Anodes

Sterndrive and Outboards are made up of a mix of different metals making them high risk to galvanic corrosion. Most outdrives are fitted with multiple anodes covering everything from, trim tabs, rams, cavitation plates and more. We recommend referring to your owners manual for the proper type and location of your zincs. Zinc anodes for outdrives can usually be purchased as individual pieces or in kits.

Sea Shield Marine carries all anodes for the popular Mercury Mercruiser Alpha and Bravo series outdrives. Seashieldmarine.com/Mercruiser_Anodes

Engine/Heat Exchangers

Heat exchangers are typically made with a copper alloy which makes them prone to corrosion. To help protect them most heat exchangers are outfitted with “pencil” zincs. Pencil zincs or engine anodes are located under a brass plug on the exchanger. Seashieldmarine.com/Pencil_Zincs

scotthoadley

Previous post the worlds most trusted marine anodes, next post video: how is boating good for the u.s. economy, leave a reply cancel reply.

Save my name, email, and website in this browser for the next time I comment.

GENERAL BOATING ANODES

- NEW PRODUCTS

- SHAFT ANODES

- TRIM-TAB & RUDDER ANODES

- HULL ANODES

- STERN/OUT-DRIVE ANODES

- PROPELLER ANODES

- BOW THRUSTER ANODES

- SAILDRIVE ANODES

- KEEL COOLER ANODES

- ENGINE ANODES

COMMERCIAL ANODES

- HEAT EXCHANGER

- LOBSTER & CRAB TRAPS

- MOORING CHAINS

INDUSTRIAL ANODES

- BALLAST TANK

- PIER & PILING

- UNDERGROUND

- WATER SCREENS

- REQUEST A QUOTE

- DEALER INFORMATION

EMAIL SIGN-UP

© 2024 Sea Shield Marine Products, Inc..

- Streamline Collars

- Metric Streamline Collars

- Limited Clearance Collars

- Micro Limited Clearance Collars

- SALCA Line Cutter Anodes

- Metric SALCA

- Beneteau Collars

- Rudder & Trim Tab Anodes

- Cranchi / Azimut Yachts

- Bennet Trim Tab Anodes

- Bolt-On Anodes

- Weld-On Anodes

- Solid Plate Anodes

- Mercruiser Quick-Change Anodes

- Mercruiser Anodes

- Volvo Penta Anodes

- Mercruiser Anode Kits

- Prop Nut Anodes

- Beneteau Prop Nuts

- Yanmar Saildrive Anodes

- Fernstrum keel Cooler Anodes

- Frigoboat Keel Cooler Anodes

- Anodes With Or Without Plug

- Magnesium Anodes

- New Products

- Download Catalogue

- Dealer Information

- 2024 BOAT BUYERS GUIDE

- Email Newsletters

- Boat of the Year

- 2024 Freshwater Boat and Gear Buyers Guide

- 2024 Boat Buyers Guide

- 2024 Water Sports Boat Buyers Guide

- 2024 Pontoon Boat Buyers Guide

- Cruising Boats

- Pontoon Boats

- Fishing Boats

- Personal Watercraft

- Water Sports

- Boat Walkthroughs

- What To Look For

- Watersports Favorites Spring 2022

- Boating Lab

- Boating Safety

- Ultimate Boating Giveaway

Choosing the Right Sacrificial Anode

- By Kevin Falvey

- Updated: August 24, 2023

Complex and mysterious, corrosion is as dear to boaters’ hearts as their credit card balances are. In past marine corrosion articles, I’ve delivered straight science.

This time, I’m taking a colloquial approach. Here goes.

Corrosion is like the uninvited guest who always shows up hungry. At some point, you forget about serving this goat a meal and dish out snacks and junk food to keep him away from the roast beef. With corrosion, you feed the unwelcome guest excess electrons instead of Twinkies. These electrons come ready to eat, “packaged” in the form of what are called sacrificial anodes. Corrosion eats the anode (the Twinkie) instead of your sterndrive, prop shaft or raw water through-hull (the good stuff) because anodic metals dish out electrons as freely as Grandma dishes out Thanksgiving dinner. Know that with each electron consumed, a minute bit of the anode’s metal is consumed instead of a bit of your boat or drive’s metal , hence the sacrificial moniker.

Now, most boaters refer to sacrificial anodes as “zincs,” because zinc has been used for a long time. But there are other “zincs” made of aluminum, magnesium and various alloys with various trade names. In many cases non-zinc anodes outperform actual zinc anodes, depending upon the type of metal you need to protect and the nature of the water in which the metal being protected is immersed. It all has to do with the voltage of the anode when referenced against a standard. The standard is an electrode made of silver/silver chloride. That just means they are relative: The higher the anode’s voltage, the more freely it gives up electrons and the more able it is to feed corrosion. We are talking about negative voltage here, so wrap your mind around the concept of “more negative voltage.”

Pros of Zinc Anodes

Zinc anodes are typically best for boats used in salt water because they are the most reactive to seawater’s electrolytes. Zinc is a less stable metal than the stainless-steel and aluminum components of an outboard, so if a circuit is created due to saltwater immersion, zinc will be the first to shed electrons, or corrode, thus sacrificing itself to protect the motor.

Cons of Zinc Anodes

Zinc is not effective in fresh water, and its use has raised environmental concerns because it leaches cadmium into the water as it corrodes.

Price of Zinc Anodes

$42; westmarine.com

At a glance, you might conclude that, since magnesium has the highest negative voltage, that’s the anode to use to protect any metal, on any boat. But it’s not.

Anodes create electrical current by setting up a difference in electrical potential. More is better in the sense that it’s the equivalent of a tastier dish that your guest, corrosion, will devour readily. But suppose you run out of snacks?

Pros of Magnesium Anodes

If you boat in fresh water, you’ll definitely want to choose magnesium anodes over zinc because they work better in fresh water’s lower-conductivity environment. While aluminum anodes work well too, magnesium is the best choice for fresh water.

Cons of Magnesium Anodes

Magnesium anodes are super reactive in salt water and will quickly deteriorate, leaving your outdrive or lower unit exposed to galvanic corrosion once the magnesium has given up the ghost. Be mindful if you take your freshwater boat into salt.

Price of Magnesium Anodes

$55; westmarine.com

Magnesium has a low current capacity. Like a bowl of nuts, it’s quickly eaten. Zinc and aluminum are akin to a plate piled high with home cooking. The meal lasts longer. So, though magnesium offers more protective electrons faster, it protects for only about one-third the time of zinc, and just one-fifth the time of aluminum. In a hypothetical situation where zinc would last 150 days, magnesium would last but 50 days, while an aluminum anode would have corrosion lined up at the chow line for 225 days.

Additionally, the high rate of electrons served up by magnesium can create too much current — i.e., “overprotect” — when used to protect a metal that itself is already very active, like aluminum, especially one used in waters that are more conductive of electricity. This means salt water and polluted fresh water. In fact, if you take a freshwater boat protected by magnesium anodes to the coast and put it in a slip for a week, you’ll have a catastrophe on your hands.

Pros of Aluminum Anodes

Aluminum anodes have been touted because they work in fresh and salt water. They are typically lighter than zinc anodes and do not release cadmium into the water as they corrode. Aluminum anodes also tend to cost less than zinc anodes and last longer. They are not pure aluminum but made of an alloy designed for use as a sacrificial anode.

Cons of Aluminum Anodes

The quality of aluminum anodes can vary based on the alloy used to make them. Seek out the highest-quality aluminum anodes.

Price of Aluminum Anodes

$32; westmarine.com

So, how do you choose which anode type to use on your boat? Cost helps answer the question. Magnesium is more expensive than zinc, and zinc is more expensive than aluminum. Additionally, comparing zinc and aluminum, besides their carrying capacities, which bear on your length of season, zinc forms an insulating oxide film over itself, especially in fresh water, that stops it from working. In fact, if you have an anode that seems never to have worn away, it’s probably oxidized and not doing its job! By mixing iridium and other metals with aluminum, alloys are created that don’t form aluminum oxide.

See the chart (above) showing general guidelines for choosing an anode type based on the metal needing protection and its location.

There are other considerations. For example, if your boat is connected to shore power, and thus connected to all the other boats at the dock, you may choose “weaker” zinc over aluminum to minimize the electrical activity. But if your boat has a galvanic isolator, or you’re not plugged in, the more active anode might be a better choice.

Confused? Here’s the takeaway.

The principles presented should have raised your anode awareness. They give you the basis to raise the right questions. Seek out a mechanic with ABYC “Marine Electrical” or “Marine Corrosion” certification and have the conversation. Don’t just buy an anode kit because it has your engine’s brand on it.

- More: comparisons , How-To , October 2023 , Preventative Care , spring fitting-out

More How To

Compounding Mistakes Make for a Dangerous Situation

On Board With: Monique Richter

Grady-White Pulls off Its Largest Raft-up Ever in Vieques, Puerto Rico

Installing Retractable Transom Straps

Boat Test: 2024 Grady-White 231 Coastal Explorer

Boat Test: 2024 Hurricane SunDeck 2600 OB

Boat Test: 2024 Brabus Shadow 1200 Sun-Top

Inflatable Water Mats for Boaters

- Digital Edition

- Customer Service

- Privacy Policy

- Terms of Use

- Cruising World

- Sailing World

- Salt Water Sportsman

- Sport Fishing

- Wakeboarding

Many products featured on this site were editorially chosen. Boating may receive financial compensation for products purchased through this site.

Copyright © 2024 Boating Firecrown . All rights reserved. Reproduction in whole or in part without permission is prohibited.

(774) 328-9232

- Aluminum Hull Anodes

- Honda Aluminum Anodes

- Mercruiser Aluminum Anodes

- Mercury Aluminum Anodes

- OMC Aluminum Anodes

- Rudder & Trim Tab Aluminum Anodes

- Shaft Aluminum Anodes

- SUZUKI Aluminum Anodes

- Volvo Aluminum Anodes

- Yamaha Aluminum Anodes

- Saildrive Aluminum Anodes

- Johnson Evinrude Aluminum Anodes

- Yanmar Aluminum Anodes

- Aluminum Bow Thruster Anodes

- De-Icer Ice Eater Aluminum Anode

- Spur Aluminum Line Cutter Anodes

- Honda Magnesium Anodes

- Hull Magnesium Anodes

- Johnson Evinrude BRP Magnesium Anodes

- Mercruiser Magnesium Anodes

- Mercury Magnesium Anodes

- OMC Magnesium Anodes

- Rudder & Trim Tab Magnesium Anodes

- Shaft Magnesium Anode

- Suzuki Magnesium Anodes

- Volvo Magnesium Anodes

- Yamaha Magnesium Anodes

- Yanmar Magnesium Anodes

- Spur Magnesium Line Cutter Anodes

- Saildrive Magnesium Anodes

- Bow Thruster Zinc Anodes

- Crab Trap Zinc Anode

- Engine Pencil Zinc Anodes

- Hamilton Jet Drive Zinc Anodes

- Honda Zinc Anodes

- Hull Zinc Anodes

- Ice Eater - De-Icer Zinc Anodes

- Johnson Evinrude OMC Outboard Zinc

- Keel Cooler Zinc Anodes

- Mercruiser Zinc Anodes

- Mercury Zinc Anodes

- OMC Zinc Anodes

- Propeller Zinc Anodes

- Rudder & Trim Tab Zinc Anodes

- Saildrive Zinc Anodes

- Shaft Zinc Anodes

- Suspended Zinc Anodes

- Suzuki Zinc Anodes

- Volvo Zinc Anodes

- Yamaha Zinc Anodes

- Yanmar Zinc Anodes

- Spur Line Cutter Zinc Anodes

- Lobster Buoy Paint and Coating

- Ablative Bottom Paint

- Inflatable Bottom Paint

- Topside Paint

- Outdrive and Prop Paint

- Boat Stands

- Create account

Top-Selling Boat Care Essentials: Zincs, Paint & Boat Stands

Aluminum Anode Kit For Mercruiser Alpha 1 Generation 2 Includes Hardware

Coastal Copper 250 Ablative Antifouling Marine Paint Blue Gallon

Coastal Copper 450 Bottom Paint - Black Gallon

Mercruiser Alpha 1 Gen 1 & MR Magnesium Anode Kit For Freshwater Use

Mercruiser Bravo 1 Aluminum Anode Kit

Mercruiser Bravo 2 and 3 Zinc Anode Kit Includes Hardware 97-888761Q04

Mercruiser Bravo 3 Zinc Anode Kit 2004 & Newer Includes Hardware 97-888761Q04

Mercury Optimax 75 - 250 HP Zinc Anode Kit Includes Hardware

Mercury Verado 6 Cyl Magnesium Anode Kit For Freshwater Use

N1 Hull Zinc Anode Downeast Style TEC N1

R3 Rudder & Trim Tab Zinc Anode

R4 Rudder & Trim Tab Zinc Anode

TEC-DIVERS DP1 HULL PLATE ZINC 12" X 6" X 1/2" MILITARY GRADE ZINC

Volvo 290 DP Dual Prop Magnesium Anode Kit For Freshwater Use

X5 Shaft Zinc Anode 1 1/4 Inch Shaft

X7 Shaft Zinc Anode 1 1/2 Inch Shaft

X8 Shaft Zinc Anode 1 3/4 Inch Shaft

X9 Shaft Zinc Anode 2 Inch Shaft

Zinc Anode Kit Fits Volvo Penta 280 Single Prop Outdrive Includes Hardware Replaces V-18 875815-3 and 832598

Zinc Anode Kit Fits Volvo Penta 290 Single Prop Includes Hardware Replaces Volvo V-18A (875815-3), Volvo 852835

Zinc Anode Kit For Mercruiser Alpha 1 Generation 2 Includes Hardware Replaces 97-888755K01

Zinc Anode Kit For Mercruiser Bravo 1 Includes Hardware Replaces 97-888758Q02

Zinc Anode Kit For OMC Cobra Includes Hardware

Zinc Anode Kit For Volvo Penta 290 DP Dual Propeller Full Zinc Kit With Hardware Replaces Volvo Penta 875821, 852835

Zinc Anode Kit For Volvo Penta SX And DP-SM Outdrives Includes Hardware

Zinc Anode Kit For Yamaha 150 - 200 Hp Right Hand Regular Rotation Includes Hardware

Zinc Anode Kit For Yamaha 200 - 250 HP Includes Hardware

Zincs for Boats | (774) 328-9232

What Are Zincs On A Boat And Do They Need To Be Replaced?

*This post may have affiliate links, which means I may receive commissions if you choose to purchase through links I provide (at no extra cost to you). As an Amazon Associate I earn from qualifying purchases. Please read my disclaimer for additional details..

Boat maintenance may be the most challenging part of owning a boat. There are a lot of things to be taken care of on a regular basis. Corrosion is one of the greatest enemies of the fixtures on a boat and its machinery.

Inevitably, because of the constant exposure to the sea, corrosion cannot be avoided but there are ways to protect against it. The use of anodes is one main way.

What Are Anodes On A Boat?

Anodes are very important for coping with the large issue of corrosion on a boat. They are pieces of metal different from the parent material they are attached to that lessen the corrosive effect of seawater on the parent material.

A main component of ship architecture is often iron, and iron is also the metal most prone to corrosion. From the smallest nuts to the main body of the boat, everything is at risk of corrosion. Protecting the structural iron components is crucial to the stability of the boat.

Commonly known as sacrificial anodes, there are three types of metals used for this purpose—zinc, aluminum, and magnesium. The best out of these are zinc anodes because of the hydrogen activity of zinc when it is in contact with seawater. When placed over or near metallic parts, zinc anodes help protect boat parts from corrosion.

Also known as a galvanic anode, its strongly negative reduction potential protects the other less negative metals such as iron and aluminum. The zinc anodes themselves actually take on the corrosion while keeping the underneath metallic boat part completely safe.

Whenever any oxidant comes in contact with the boat, such as seawater, the zinc anode draws the oxidizing effects away from the iron. In this way, the important boat parts are kept safe from corrosion. The best use of zinc anodes is in saltwater.

They are commonly used in tanks, rudders, piers, and boat hulls. They can also be used in underground piping and tanks.

While in freshwater, zinc anodes produce a zinc hydroxide film which hinders the electron flow . Due to this reason, zinc is much more effective in seawater but not at all usable in freshwater.

Why Does a Boat Need Zinc Anodes?

As explained earlier, zinc anodes are crucial for the proper maintenance of a boat. Galvanic corrosions will surely occur when two dissimilar metals are present in a conductive solution.

Like other sacrificial anodes, zinc anodes work on the principle of electrolysis. According to this principle, if an anode atop a metallic strip is immersed in a conductive solution, the anodic electron will deposit over the metallic strip converting it to a cathode.

Coming to the underwater scenario where boats are present, seawater acts as an electrolyte. This electrolyte shifts the electrons from the anode to the steel plate. This makes a protective layer over the metal. Thus, the zinc anode is corroded in place of the steel surface.

This protective ability depends on the mass of the zinc anode. The greater the mass of the zinc anode, the greater the protection.

Another important thing is the zinc anode’s utilization factor. This factor specifies for how long the zinc anode will not lose its protective potential.

With these factors calculated, one can specify how much anode mass would be needed for a particular application. Using good quality zinc metal is also very important.

How Much Zinc Is Enough?

There can be many ways of finding out how many zinc anodes will be enough for protecting underwater metals. By a general rule of thumb, it is thought that 1 to 2 % coverage is enough.

However, it is not as simple as it looks. Many factors are collectively responsible for galvanic corrosion, and consequently, determine the percentage of zinc anodes to be used.

Some of these main factors include salinity, temperature, and levels of pollution. These factors check the effectiveness of the zinc anodes. As the levels of these factors differ from place to place, so will the number of zinc anodes vary. Some other major factors playing a huge role in the depletion of the zinc anodes include water flow and stray currents.

If the flow of water is great it will cause an early zinc anode depletion. Thorough monitoring of your zinc anodes will let you determine how much zinc is enough.

When To Replace Zinc Anodes?

Yes, zinc anodes need to be changed when they become of no use. There cannot be a specific time frame for the changing of zinc anodes, however, there are a few indicators that will help you understand when they need to be replaced.

Monitoring your boat’s voltage input and output can help you determine when the anodes should be replaced.

Having faulty voltage can cause early corrosion of your zinc anodes. With normal voltage levels, your zinc anodes can last more than 12 to 14 months.

There is no fixed time frame as it depends on the salinity, water flow, temperature, and pollution levels when do you need to replace your zinc anodes. Keeping it general, though, you can change your zinc anodes after 50% depletion.

Even before this time, if you find zinc residues on the shaft or rudder of the boat, it’s time to replace your zinc anodes. Whenever you need to get the zinc anodes checked or replaced, you need to get a certified technician. They can better inspect your boat’s voltage and the condition of zinc anodes.

How Often Do Zinc Anodes Need To Be Changed?

As explained earlier, there can be no fixed time frame for changing the zinc anodes. But still, you cannot keep the zinc anodes forever. They need to be changed now and then depending on their condition. The frequency of changing the anodes also depends on the location where the anodes are fixed on the boat.

If placed on the ship’s hull, the zinc anodes can be checked at least every 2 to 3 years, but depending on the water conditions, they may need to be checked and replaced more often.

Benefits of Using Zinc Anodes

Zinc anodes, or any other sacrificial anodes, provide several important benefits to your boat. Some of which are given here:

- They increase the durability of the ship by reducing the chances of galvanic corrosion.

- They are extremely easy to install with simple bolts and brackets.

- They work without any external power source.

- https://www.corrosionpedia.com/definition/4326/zinc-anode

- https://www.marineinsight.com/tech/understanding-sacrificial-anodes-on-ships/

- https://www.deepblueyachtsupply.com/importance-of-zinc-anodes

Similar Posts

Are Marina Slips with Dock Boxes Worth It?

*This post may have affiliate links, which means I may receive commissions if you choose to purchase through links I provide (at no extra cost to you). As an Amazon Associate I earn from qualifying purchases. Please read my disclaimer for additional details.. Marinas look for ways to make money and create a better customer…

Where Do Boats Dump Their Waste?

*This post may have affiliate links, which means I may receive commissions if you choose to purchase through links I provide (at no extra cost to you). As an Amazon Associate I earn from qualifying purchases. Please read my disclaimer for additional details.. Boats are awesome. They are amazing vehicles that make being out on…

7 Best Automatic Trim Tabs

*This post may have affiliate links, which means I may receive commissions if you choose to purchase through links I provide (at no extra cost to you). As an Amazon Associate I earn from qualifying purchases. Please read my disclaimer for additional details.. Boating is relaxing and fun. Did you know there is a way…

Can You Dump GREY Water in a Marina?

*This post may have affiliate links, which means I may receive commissions if you choose to purchase through links I provide (at no extra cost to you). As an Amazon Associate I earn from qualifying purchases. Please read my disclaimer for additional details.. If you’re lucky enough to have or are thinking of buying a…

Is Marina Electricity Metered?

*This post may have affiliate links, which means I may receive commissions if you choose to purchase through links I provide (at no extra cost to you). As an Amazon Associate I earn from qualifying purchases. Please read my disclaimer for additional details.. One of the best things about staying at a marina is the…

Tips for Cleaning Your Boat After It Has Been in Saltwater

*This post may have affiliate links, which means I may receive commissions if you choose to purchase through links I provide (at no extra cost to you). As an Amazon Associate I earn from qualifying purchases. Please read my disclaimer for additional details.. When the sun is out, boat owners feel something familiar pulling them…

Boats & Zinc Anodes: Helpful Answers (For Beginners)

What are zinc anodes, and what is their purpose on a boat?

This article will go over zinc anodes, what they are, what their purpose is on a boat, and several other boating questions that you may not have even known you had.

Without further ado, let’s dive into those boating questions!

Table of Contents

What Are Zinc Anodes?

Zinc anodes are essentially a metal attachment to the boat’s underwater part, often on a propeller shaft or the propeller.

Basically, a zinc anode is designed to be the thing on your boat that corrodes instead of any steel or other metal components of your boat – like the engine and propeller.

Why would you want the metal to do this?

You want to prevent a process called Galvanic Corrosion in your engine and drivetrain.

What is Galvanic Corrosion?

When two different metals physically connect in seawater, an electrical current flows between them like a battery.

For this current to exist, one of the metals has to give up pieces of itself.

The reason zinc has to give up pieces of itself is because electrons are created as the metal dissolves, generating the current between the two metals.

This deterioration of metals is what’s known as Galvanic Corrosion.

Let’s go over why you put zinc anodes on boats.

What is the Purpose of a Zinc Anode on a Boat?

As we mentioned, zinc anodes aid in keeping the important metals on your boat from corroding.

Your boat will typically have at least two metals built within it, but zinc is a third metal added for it to be intentionally sacrificed. Basically, the zinc will break itself down instead of the other two boat metals.

Zinc anodes are the unsung hero of protecting your boat’s metal and mechanical equipment.

Since your boat will often be on the water, having a zinc anode is necessary to keep your boat’s engine and propeller lasting a long time.

What Are the Different Types of Anodes?

Now that you know what zinc anodes are, it’s important to have a working knowledge of the other types of anodes you can put on a boat since all boats are not created equal.

Knowing what kind of metals are on your boat will help you know what kind of anode is appropriate for your boat and protect your boat.

Let’s go through the different kinds of anodes so you have an idea of what anode would be a good fit for your boat:

The first type of metal used for an anode is zinc, which we have covered.

This is the most common since it is the easiest to attain.

Zinc works pretty well on most types of boats and will prevent corrosion of your boat’s metal parts in saltwater quite well.

However, zinc is also a fairly heavy metal and has been shown to not be entirely beneficial to the environment.

The second anode material is aluminum.

Aluminum has recently started to replace zinc as the more commonly used anode on boats used in freshwater. Aluminum is a light-weight metal and is versatile in more than just saltwater.

In addition to being a more versatile anode, aluminum also lasts longer than zinc.

Research has shown that aluminum will last 50% longer in saltwater than will zinc.

Magnesium is the third anode.

Magnesium is the most active anode, meaning that it has the shortest lifespan of the three anodes.

However, magnesium has been shown to be very non-toxic and harmful to the environment and aquatic sea life.

Which Anode Should I Choose?

The type of anode you choose will depend on which type of water your boat will be in.

There are three different types of water for anodes: saltwater, freshwater, and brackish water.

Let’s go over which anode is the most ideal for each water type:

In saltwater, aluminum and zinc will be great choices.

Aluminum will last a fairly long time in saltwater and will provide your boat with excellent protection.

Zinc won’t last quite as long but is much easier to attain, so it may be the more practical anode to use in saltwater.

Brackish Water:

In brackish water, aluminum anodes will be the ideal anode to use.

Aluminum doesn’t corrode nearly as fast as magnesium and will protect your boat against brackish water much better than zinc.

Freshwater:

In freshwater, magnesium is your best anode to use for boat protection.

The material is very conductive in freshwater, so magnesium is ideally suited to protect your boat in freshwater.

If you are more likely to be driving your boat in saltwater, zinc, or aluminum will be your ideal anode choice to ensure your boat’s metals are properly protected.

How Many Zinc Anodes Do You Need?

This number won’t be the same for every boat operator and driver, as different boats come in different sizes and materials, such as steel vs. aluminum hulls.

To find out how many zinc anodes you need for your boat, you will need to know your boat’s size, particularly its weight.

Then you need to calculate the amount of hull surface area that will be touching water and the density and energy content.

This is a formula that was pulled from www.boatzincs.com , which illustrates the complexity of this formula.

Anode Weight (lbs) = [(Wetted Surface Area) x (Current Density) x (Immersion)] [(Energy Content) x (1000 mA/Amp)]

If you are a beginner, it is probably better to contact your manufacturer or provider, who can walk you through the process or calculate it for you.

Can You “Over Zinc” a Boat?

You can “over zinc” your boat if it is made of steel or aluminum, and it will lead to significant damage if left on your boat over a long period of time.

If your boat is made of fiberglass or has material made of fiberglass, then over zincing won’t be as big of an issue.

However, if your boat is made of more traditional metal material, then over zincing is something you’ll want to keep an eye out for.

Can Zinc Rust in Water?

Zinc can “rust” in water, but it is really corroding to a white color while the other metals do not rust or corrode.

This is why it’s an ideal anode for protecting your boat’s exterior and all of the other metals on your boat.

Zinc truly acts as a silent protector for your boat.

When Should You Replace Zinc on a Boat?

Zinc won’t last forever, and you will need to replace it regularly.

When exactly do you need to replace zinc to optimize your boat’s protection?

Since the anode will provide more protection when it has more mass, you’ll need to monitor your zinc anodes’ weight.

When the zinc anode has dropped in about half of its original weight, it’s time to replace the zinc with new anodes. If it breaks apart when you try to loosen it, it needs to be replaced.

Ideally, you can expect a zinc anode to last about a year if the boat is kept in the water year-round.

This will be impacted by various factors, including driving time, water conditions, and much more.

Do Zinc Anodes Work in Freshwater?

In the battle of which anode works best in different water, it was concluded that magnesium was the winner of the best anode for freshwater.

Unfortunately, zinc is far less useful in freshwater than in saltwater.

Due to the low-current conditions in freshwater, zinc will be unable to provide adequate protection of your boat’s metals.

However, if you find yourself driving your boat in freshwater, magnesium is the best choice.

How Long Do Boat Anodes Last?

This is not an exact answer as the number will be affected by several differing factors:

- We determined that zinc should last on your boat about a year or more.

- If your boat anodes don’t last at least a year, you may need to get new or heavier anodes.

- Ideally, boat anodes last as long as they take to get down to about half of their weight.

- Whenever your anode is this size, you’ll want to replace the anode as promptly as you can.

A few things that affect how long your anodes last include the type of water in which you drive, the type of boat you have, and the frequency at which you drive your boat.

Do I Need an Anode on My Boat?

Even if you drive a small boat, protection from corrosion is essential to maintaining a long lifespan.

Using an anode is crucial, and your boat should have anodes, no matter what kind they are.

As long as they are best suited for your boat and the water type, anodes should definitely be on your boat or your engine if you have an outboard.

References:

About Corrosion – nautechmarine.co.nz

Anode Weight Calculation Formula

Click to share...

- Shaft Anodes

- Rudder & Trim Tab Anodes

- Miscellaneous

- Hull Anodes

- Collar Anodes

- Engine Anodes

- Complete - PRO Style

- Brass Plugs

- Caterpillar - Hex Plugs

- Caterpillar - Square Plugs

- Cummins/Onan

- Detroit Diesel

- Volvo Penta

- ZDM/Galvion

- Other Engine Anodes

- Propeller Anodes

- Prop Nut Anodes

- Azimut/Radice

- Mercury/Mercruiser

- Sterndrive Anodes

- Volvo Penta IPS

- Jet Drive Anodes

- Hamilton Jet

- Outboard Anodes

- Johnson/Evinrude

- Bow Thruster Anodes

- Side-Power (Sleipner)

- Twin Disc BCS

- Saildrive Anodes

- Technodrive

- Keel Cooler Anodes

- Other Pleasurecraft Anodes

- Bennett Trim Tabs

- H+B Technics

- Hanging Anodes

- Kasco De-Icer

- Sea Strainers

- Spurs Line Cutters

- TRAC Stabilizers

- Commercial Anodes

- Heat Exchanger

- Hull Anodes - Bolt On

- Hull Anodes - Weld On

- Zinc Plates

- Replacement

- Corrosion Reference Electrode

- Paint Stencils

- Rubber Backing Pads

- Shaft Polishing Strip

- Shaft Tape Measure

- ULTRA Tef-Gel

- T-Handle Hex Wrenches

SAME DAY SHIPPING on all orders placed by 4:00 PM ET

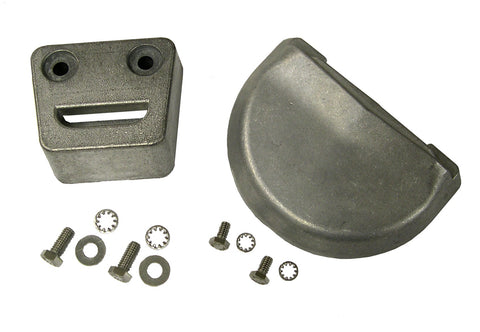

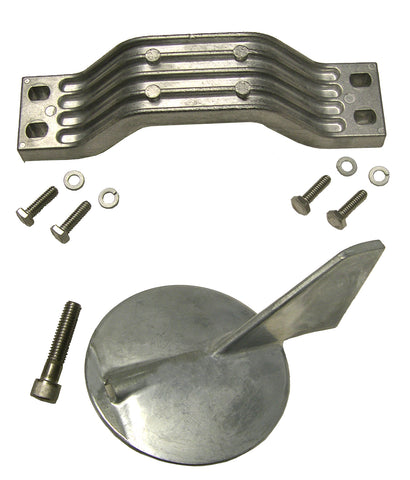

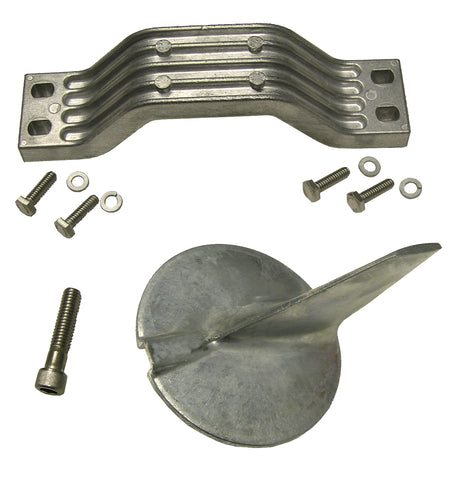

Rudder & Trim Tab Zinc Anodes – Two-Piece

- Two-piece, pancake-style zinc anode for rudders and trim tabs.

- A stainless steel nut is pressed into one piece.

- A stainless steel socket cap screw (allen head) connects the two halves together.

Part Number Variations: R-1, R1, CMR01, CMR01Z, CMR-1, R-2, R2, CMR02, CMR02Z, R-3, R3, CMR03, CMR-3, CMR03Z, R-4, R4, CMR04, CMR04Z, R-5, R5, CMR05, CMR05Z, R-7, R7, CMR07, CMR07Z, CMR1, CMR2, CMR3, CMR4, CMR5, CMR7, BNT-1, T-20, T20, 70-T20, CMT20, CMT20Z, TEC-20, T-21, T21, 70-T21, CMT21, CMT21Z, TEC-21, M-24, A-24, 70-A24, CMM24, CMM24Z, TEC-24, No. 15, #15, CAM-15, CAM 15, 70-15, Vetus-15, Vetus15, VT-15, VT15, VT-8, VT8, ZINK15C, 00220, 005090190, H2B4, H2B4-3/8, H2B4-BL, ZEP-4, ZEP4, ZD-56, ZD56, CMZD56Z, CMZD56, MGDZD565GZ, MGDZD56, 00102UK, RP-4, RP4

R-1 Rudder/Trim Tab Zinc Anode - 1-7/8" Dia.

R-2 Rudder/Trim Tab Zinc Anode - 2-13/16" Dia.

R-3 Rudder/Trim Tab Zinc Anode - 3-3/4" Dia.

R-3H Rudder/Trim Tab Zinc Anode - 4" Dia. Heavy

R-4 Rudder/Trim Tab Zinc Anode - 5" Dia.

R-5 Rudder/Trim Tab Zinc Anode - 5" Dia. Heavy

R-7 Rudder/Trim Tab Zinc Anode - 6-7/8" Dia.

IMAGES

VIDEO

COMMENTS

We are the world's largest retailer of anodes for commercial and recreational boats. BoatZincs.com is America's Superstore for Marine Anodes. We specialize in the sale of sacrificial zinc, aluminum and magnesium anodes for recreational boaters, commercial vessels, and underwater structures, and carry over 1,500 products for same-day shipping.

Fisheries Supply provides marine grade sacrificial anodes, also known as zincs or galvanic anodes, designed to protect your boat from corrosion. These highly active metals are essential for preventing the corrosion of less active materials such as propellers, and other underwater components. Our extensive inventory includes a full range of boat ...

1160 N. Halsted Street , Chicago IL 60642-4224. home. categories. boat maintenance. zincs & anodes. Sacrificial anodes are pieces of relatively pure zinc, aluminum or magnesium that are fastened to underwater boat surfaces. They are designed to wear away and protect other metal parts against damage caused by galvanic corrosion.

Mercruiser Quick-Change Anodes Mercruise Quick-Change. M-879150A65-ALU Zeus Pod Trim Tab Anode Kit (Aluminum) V-22651246 Volvo Penta 130/150 Saildrive Split Ring Zinc Anode. V-358407 Volvo Penta 130/150 Saildrive Split Ring Zinc Anode. V-40005875-ALU Volvo Penta IPS Transom Anode (Aluminum)

All our Zinc Anodes are made to MIL-SPEC standards MIL-A-18001 and our Aluminum Anodes are pressure die-cast and engineered to MIL-A-24779 ensuring longevity and precision. We carry Zinc Anodes, Aluminum Anodes, and magnesium anodes for any of your corrosion protection needs for Boats, Yachts, commercial vessels, and all types of pleasure crafts.

USA Zincs offers the absolute finest quality boat zincs and marine zinc anodes, at the lowest possible prices. We buy and sell thousands of pounds of zincs every month and our warehouse in Cape Coral, Florida is always well stocked. We are an innovator in the on-line sale of marine zinc anodes, including Rudder zincs, Shaft zincs, and Hull plates of all varieties, sizes & types.

Zinc is the traditional anode choice for saltwater vessels. All of our zinc anodes are manufactured with zinc alloy that conforms to U.S. Mil-Spec A-18001. Zinc Anodes. Shaft Anodes. Rudder & Trim Tab Anodes. Hull Anodes. Collar Anodes. Engine Anodes. Propeller Anodes. Sterndrive Anodes. Jet Drive Anodes.

Shaft Zinc Anodes - Standard (Models X-0 thru X-20) Two of the world's most popular brands of shaft zinc anodes. Regular sizes are from Camp Company. "Heavy" sizes are Reliance brand. All shaft zinc anodes have: Copper contacts that deform during installation for a permanent electrical bond.

Zimar plate marine zinc anodes meet all standards set forth by Mil-Spec A-18001K, Mil-Spec A-18001A, and Mil-Spec A-18001. Zimar plate boat zincs are individually hand poured to assure the highest possible zinc concentration and lowest amount of porosity. We carry the entire line of drilled and undrilled bolt on zinc plates, as well as weld on ...

Zinc anodes for boats can effectively reduce both galvanic and electrolytic corrosion. Zincs are considered a sacrificial anode, meaning they will deteriorate and corrode instead of the important parts of your boat corroding. In the case of galvanic and electrolytic corrosion, sacrificial anodes work by giving up their electrons before the ...

Zincs for boats protective properties result from a strongly negative reduction potential, which is more negative than the boat metal it is protecting. Oxidants, which corrode metals, will oxidize the zinc rather than the protected metal structure, thus preventing the boat from being corroded. Zinc make a great choice for a sacrificial anode because it's a highly active metal that is capable ...

Boat Zincs and Anodes. An essential part on every vessel, zinc anodes for boats are installed to protect underwater metal components, such as a bronze propeller or metal struts, from galvanic corrosion. Galvanic Corrosion occurs when two dissimilar metals are physically or electronically connected and immersed in water. Without any form of ...

Sacrificial Anodes (Zincs) stop Galvanic Corrosion. To stop Galvanic Corrosion from destroying your underwater metals you would have to disrupt the process of your boats metals sacrificing themselves to the electrical current. The solution is to add a third metal into the equation, one that sacrifices itself to protect your precious underwater ...

Here's the first step in figuring out what boat zincs really do. By Gary Reich. March 19, 2014. Working a couple of days a week at a marine supply shop offers a window into what's happening within the local boating community. It's part of what I like about the job. So this week as I watched cases of bottom paint and hundreds of boat zincs ...

Zinc anodes are typically best for boats used in salt water because they are the most reactive to seawater's electrolytes. Zinc is a less stable metal than the stainless-steel and aluminum components of an outboard, so if a circuit is created due to saltwater immersion, zinc will be the first to shed electrons, or corrode, thus sacrificing ...

Rudder zincs, Shaft zincs - boat anodes come in many different sizes. Shaft anodes usually are made up of two-piece that are fitted together around the shaft. These zincs are available in sizes to fit most propeller shafts. Rudder zincs are flat like a pancake and bolt onto the rudder and hull zincs are also flat and bolt to the hull.

Zinc Anode Kit For Yamaha 200 - 250 HP Includes Hardware. $ 30.92. Zincs for Boats is the Internet's leading wholesaler of zinc, aluminum and magnesium anodes for all boaters. We stock thousands of different products to meet all your boating needs. Visit us or call (774) 328-9232.

Whenever any oxidant comes in contact with the boat, such as seawater, the zinc anode draws the oxidizing effects away from the iron. In this way, the important boat parts are kept safe from corrosion. The best use of zinc anodes is in saltwater. They are commonly used in tanks, rudders, piers, and boat hulls.

Hull Zinc Anodes - Bolt On Zinc is the traditional anode choice for saltwater vessels. Part Number Variations: Bolt On. Add to Cart The item has been added. DP-612 Hull Zinc Anode List Price: $82.99 Our Price: $54.58. ADD The item has been added. Add to Cart The ...

Shop for your zinc shaft collar anodes now and save or browse our wide selection of propeller and drive train products. Metric shaft zinc is also available. Can't find what you're looking for? Let us help. 206-632-4462. Propeller shaft anodes or zinc shaft collar anodes, are crucial for protecting your boat's propeller shaft from corrosion.

Zinc: The first type of metal used for an anode is zinc, which we have covered. This is the most common since it is the easiest to attain. Zinc works pretty well on most types of boats and will prevent corrosion of your boat's metal parts in saltwater quite well. However, zinc is also a fairly heavy metal and has been shown to not be entirely ...

Read why there are no UPC labels on our engine anodes, here. Use our comprehensive Cross Reference for your engine anodes, here. Part Number Variations: Complete. Add to Cart The item has been added. E-00 Engine Zinc Anode - 1/8 NPT x 2" List Price: $10.49 Our ...

Rudder & Trim Tab Zinc Anodes - Two-Piece. Two-piece, pancake-style zinc anode for rudders and trim tabs. A stainless steel nut is pressed into one piece. A stainless steel socket cap screw (allen head) connects the two halves together.