Sailboat Bottom Paint: 10 Best Paints

If you leave your boat without protection, it's beyond question that it will start attracting several marine organisms such as slime, algae, mussels, barnacle, and seaweed. This will cover the bottom of your sailboat and may negatively affect your boat's speed and fuel efficiency.

This is exactly why you need to apply the best sailboat bottom paint on your boat.

The freedom that sailing and being off land gives you are immense and almost unmatched.

But do you know that having multiple organisms such as algae, slime, barnacle, seaweed, and mussels grow on your boat can throw everything out on the wind and leave you with a very unreliable boat?

These pesky hangers will put a huge dent in your boat's speed, its movement, fuel efficiency, and overall aesthetic.

That's why you need the best sailboat bottom paint to greatly minimize any damage that might be caused to your boat's hull by marine biological growth.

Also known as antifouling paint, bottom paint is essentially a paint or coating that's specifically designed with elements that prevent various marine organisms such as algae, seaweed, barnacles, slime, and mussels from attaching themselves to your boat's hull or any other part of the boat that's below the waterline.

One of the most important elements of bottom paint is the inclusion of a biocide and copper is the most common. This may, however, depend on the type of boat that you have, how, and where you always use it.

But because there's an ocean of bottom paints out there on the market, choosing the best sailboat bottom paint can be an overwhelming task for most of us.

Fortunately, you can always count on us to make it a lot easier for you. We've gone through many bottom paints and we do not doubt that we've selected the most effective, reliable, and best sailboat bottom paint.

Our unbiased selections will not only match your needs and budget but will be available in a variety of colors to complement and augment your boat's visual appeal.

Table of contents

What to Consider when Purchasing Sailboat Bottom Paint

If you're on the market for the best sailboat bottom paint, it's crucial to go for top quality; something that will offer efficiency, top speed, and excellent performance for your sailboat. With that in mind, here are a few things to consider before spending your hard-earned money on bottom paint.

Your Sailing Location

Where are you planning to sail? Is it on a freshwater body or in a saltwater location? This is essential in helping you determine whether to go for a bottom paint that's meant for saltwater, freshwater, or both. It's generally recommended that you go for a bottom paint that will serve you perfectly well in both freshwater and saltwater. This gives you the versatility of sailing anywhere without worrying about marine organisms damaging your boat's hull.

Launch Time and Recoat Time

It's important to keep in mind that bottom paint products have specific launch time limits. The idea here is to ensure that you launch it within the required timeframe and ensure that recoating is done as required. You should, therefore, choose a bottom paint that offers a lengthy launch and recoat time while offering durable protection for your vessel is the right thing to do.

Type of Boat

You should determine whether your boat is made of wood, fiberglass, or aluminum and go for bottom paint that's suitable for that particular surface. Many bottom paints work perfectly with fiberglass but some work great with aluminum or wooden surfaces.

The Fouling Condition

Having a deeper idea of the type of fouling that you might deal with can be crucial when buying the right bottom paint for you. Whether you're dealing with slime, algae, mussel, or any other type of marine organism, knowing the type of fouling you're dealing with will make it a lot easier to pick the best sailboat bottom paint for your vessel.

Best Sailboat Bottom Paint

Rust-oleum marine flat boat bottom antifouling paint.

As one of the most respected brand names in the bottom paint industry, Rust-Oleum is known for producing some of the best sailboat bottom paint and the Marine Flat Boat Bottom Antifouling Paint is one of them. This bottom pain is designed to be suitable for various conditions (both freshwater and saltwater) and is designed with moderate copper that works great if you are environment-conscious.

This bottom paint does an excellent job of offering a protective coating to ensure that your boat is free of all sorts of unwanted marine organisms. You'll love this paint because it is thick and spreads so easily and will not be a problem even if you're a beginner. This bottom paint offers top-notch antifouling properties and is very easy to apply as long as you use a soft brush and mix it carefully. This is a great bottom paint choice that will offer a sleek multi-season finish and ensure that your boat's hull is always awesome and in great condition.

- Easy and simple to apply

- Great for both freshwater and saltwater

- Offers gentle fouling conditions

- Excellent in antifouling

- Offer a sleek and awesome finish

- Quite expensive

- Has a very strong smell that can cause headache

Interlux Fiberglass Bottomkote Antifouling Paint

This is another great brand that is considered as one of the best bottom paint in the sailing world. Even though it's a bit pricey, it offers great features that will ensure that your boat remains in tip-top shape. It is an excellent option if you're looking for a sailboat bottom paint that brings to the fore a unique dual resin approach.

This is a very reliable bottom paint that will not only prevent your boat's hull from the effect of marine organisms but also prevent premature deterioration. It offers an awesome polishing action and is perfecting if you want to discard unnecessary paint buildup. This bottom paint is also very economical and a small quantity will cover a considerable surface area of your boat's bottom.

This is, without a doubt, a superb buy in terms of its practicality and economical nature. It is excellently formulated to prevent marine organisms from damaging your boat and also to ensure that premature wear and tear doesn't exist in your vocabulary.

- It's formulated with a unique dual resin approach to prevent premature wear and tear

- It prevents early decline

- It prevents unnecessary paint buildup

- Great for ensuring that your boat is fuel effective

- Great for all conditions (both freshwater and saltwater)

- It's expensive

- The quantity and size can be misleading

TotalBoat JD Select Bottom Paint

As one of the few bottom paints that's formulated with low Volatile Organic Compounds (VOC), this bottom paint is one of the most cost-effective on this list. With one gallon, you can easily cover about 400 square feet and the application is a breeze since it's even much easier to clean up.

When you purchase this bottom paint, the package will come complete with a pair of latex gloves, a wooden stir stick, an abrasive pad, a metal tray kit, a paint suit, a roller, a painter's tape, and many more. The inclusion of all these accessories makes it a quite cost-effective purchase.

Again, this is one of the most durable bottom paints. Apply it on your boat's hull and you're guaranteed that it will offer excellent protection for the next 18 months. On the downside, this paint is too thick and you'll have to buy an excellent thinner for it to work perfectly.

Nonetheless, this is an ablative bottom paint that is easy to apply and does an excellent job of protecting your boat's bottom for close to two years.

- Perfect for all conditions

- Easy to apply and clean up

- Can improve your boat's speed and fuel efficiency

- Comes with all accessories required for the paint job

- It's one of the best water-based bottom paint products in the industry

- It contains low VOC

- You'll need a top-quality thinner for it to work perfectly

Aquaguard Water-based Antifouling Bottom Paint

An excellent choice for both wooden and fiberglass boats, this is the most perfect bottom point for saltwater conditions. This is a water-based bottom paint that's very easy to apply and clean up (using soap and water) and is formulated with an ablative action that makes it superb for preventing any marine organism that may negatively affect your boat.

This is a bottom paint that is EPA-approved and surpasses the set VOC standards. It has an extended shelf life and offers durable protection for your sailboat. It doesn't contain toxic fumes and is great even for novices. Its drying time is also excellent, so you won't wait for far too long to get your boat out there on the water.

- Excellent for saltwater conditions

- Application and cleaning is very easy

- It's approved by the US EPA

- You don't have to use a primer

- The color selection is limited

- A bit pricey

Pettit Hydrocoat

This is another water-based bottom paint that offers outstanding ablative properties that will protect your boat from marine organisms throughout the seasons. It offers good value for money and is easy to apply and clean up with just water and soap.

We're talking about a bottom paint product that will protect your boat's hull for months on end. You also do not need a full tank of the paint to complete the job. With just a single gallon, you can be sure to complete an area as big as 430 square feet.

This is also one of the few bottom paints that can perfectly prevent your boat from damage when being trailered, launched, or beached. More importantly, it's not irritating to the nose and eyes because it has low VOC.

- It will dry in 3 hours

- It's easy to apply and clean up

- It offers multi-season protection

- It's not irritating to the eyes and nose

- It's quite economical

- May not be the best in antifouling

- You have to apply at least two coats

SEA HAWK PAINTS Aluminum Boat Paint

One of the best aluminum boat paints in the market, this bottom paint is formulated to offer quick-dry corrosion-blocking, high-solid features. This bottom paint is specifically manufactured to be used in aluminum boats and doesn't require the addition of any primer.

While it doesn't have an antifouling feature, it stands out and can be used both below and above the waterline as it is risk-free and free or chromate. It is also formulated to offer a unique dual resin approach and can be used both as paint and a primer at the same time.

This is a great paint for both freshwater and saltwater conditions and can be applied as a primer or topcoat on a fiberglass boat. This is an excellent sailboat boat bottom paint that's worth every coin as it is practical, versatile, and can combat both rusting and lifting.

- The application and cleanup process is easy

- Great for both freshwater and saltwater conditions

- It doesn't require a primer

- Can be used as primer or topcoat in fiberglass boats

- Can prevent rusting and lifting

- It has quick-dry and anti-corrosion features

- Can produce deadly fumes

TotalBoat Spartan Boat Bottom Paint

If you've been looking for a practical, reliable, and cost-effecting bottom paint that will offer durable performance and protection, the Spartan Boat Bottom Paint. Perfect for both freshwater and saltwater, it can be perfect for protecting your boat and ensuring that it is fuel-efficient and reliable.

This bottom paint is formulated with advanced copolymer ablative to ensure that it doesn't deteriorate instantly. This is a very dependable bottom paint that will serve you perfectly throughout the year and will ensure that your boat easily defies fouling while reducing unnecessary buildup and sanding on your boat.

This is a very adaptable bottom paint that not only offers great value for money but is very easy to apply. More importantly, it is very durable and will protect your vessel for at least 12 months on any type of water.

- Great for all types of water

- It offers a very durable protection

- Available in a wide variety of color selection

- Offer a visually appealing abrasion-proof finish

- The included accessories aren't up to the right quality

To this end, we must put a lot of emphasis on the importance of having the right bottom paint for your boat. In addition to being an antifouling agent, bottom paint will significantly increase the fuel efficiency of your boat and ensure that it performs optimally at all times. Of course, you do not want to diminish your sailing escapades or have your nice and beautiful vessel damaged by marine organisms just because you didn't apply the right sailboat bottom paint. If you're unsure how to proceed, here's how to paint a sailboat.

Related Articles

Daniel Wade

I've personally had thousands of questions about sailing and sailboats over the years. As I learn and experience sailing, and the community, I share the answers that work and make sense to me, here on Life of Sailing.

by this author

Repairs and Maintenance

Sailboat Upgrades

Most Recent

What Does "Sailing By The Lee" Mean?

October 3, 2023

The Best Sailing Schools And Programs: Reviews & Ratings

September 26, 2023

Important Legal Info

Lifeofsailing.com is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon. This site also participates in other affiliate programs and is compensated for referring traffic and business to these companies.

Similar Posts

How To Choose The Right Sailing Instructor

August 16, 2023

Cost To Sail Around The World

May 16, 2023

Small Sailboat Sizes: A Complete Guide

October 30, 2022

Popular Posts

Best Liveaboard Catamaran Sailboats

December 28, 2023

Can a Novice Sail Around the World?

Elizabeth O'Malley

June 15, 2022

4 Best Electric Outboard Motors

How Long Did It Take The Vikings To Sail To England?

10 Best Sailboat Brands (And Why)

December 20, 2023

7 Best Places To Liveaboard A Sailboat

Boat Reviews

- Boats Specs

- Marine Pros

- Boat Insurance

- Boat Warranties

- Boat Transport

- Boat Towing

- Marine Forecasts

Your Ultimate Boating Resource

Sailing Smoothly: The Best Guide to Selecting the Perfect Bottom Paint for Your Boat

Maintaining your boat’s performance and longevity is deeply anchored in the choice of the right bottom paint. It’s not just about aesthetics; it’s about creating a shield against marine life that can slow you down.

Dive into this all-encompassing guide to discover how the right bottom paint, tailored to your boating lifestyle, can make a world of difference.

The Vital Role of Bottom Paint

Think of your boat’s hull as a warrior in constant battle against underwater foes. Without bottom paint, it’s vulnerable to fouling, which can lead to reduced speed and efficiency. The secret weapon? Bottom paint infused with biocides that repel these unwelcome guests, keeping your hull sleek and swift.

Exploring the Seas of Bottom Paint Choices

Navigating the world of bottom paints can be like sailing through uncharted waters. There’s hard paint for the long haul, ablative paint that gracefully wears away with use, and even eco-friendly options that embrace green sailing. Each type has its unique strengths, so your choice should reflect your nautical needs.

The Copper Conundrum

Copper-based paints have long been the go-to for their fouling-fighting prowess. But as we become more conscious of our environmental impact, it’s important to weigh the effectiveness against potential ecological concerns.

Tailoring Paint to Your Boating Style

Your boating habits are the compass that guides your choice of bottom paint. Whether you’re leisurely cruising or racing against the wind, there’s a paint that aligns perfectly with your aquatic adventures:

Cruising Boats

With sleek and sturdy boats, their hulls coated in durable paint, resist the corrosive forces of time and tide. These vessels offer unwavering protection, allowing you to sail confidently through any weather conditions.

Racing Boats

For those seeking speed, ablative paints provide a slick and clean surface that is crucial for cutting through the waves. Their sleek, streamlined bodies sliced through the water with precision and speed. Each boat was coated in a shimmering layer of ablative paint, creating a smooth and clean surface that was essential for achieving maximum velocity.

Factors to Navigate When Choosing Paint

The waters you sail, the material of your hull, and even local laws are crucial markers in your journey to the perfect paint:

As you glide through the vast expanse of ocean, the type of water beneath your boat plays a crucial role in determining the ideal paint for your vessel. The crystal clear waters of a freshwater lake call for a different coating than the salty waves of the open sea. And even the laws and regulations of the local area can impact your choice of paint.

Hull Material

Selecting the hull material for your boat is like choosing a vessel as a sailor. The material you choose will play a crucial role in determining which type of paint will adhere best and provide optimal protection for your boat. Think carefully about your options, for the material itself can greatly impact the performance and longevity of your watercraft on the open seas.

DIY or Professional

Taking on a DIY project can be both exciting and daunting. Are you confident in your skills to paint your own ship, or will you leave it to the professionals? Consider the type of paint you choose–some are more forgiving for those without professional experience. As you set out on this endeavor, envision yourself as a deckhand navigating rough seas, armed with your chosen brush and paint, ready to transform your ship into a masterpiece.

Local Rules of the Sea

As you sail the open sea, always keep a vigilant watch on the horizon for any local regulations that may dictate your voyage. Pay special attention to any restrictions regarding copper-based options, as they may affect your journey in unexpected ways. Stay informed and navigate confidently to ensure smooth sailing ahead.

Final Thoughts

Your boat is more than a vessel; it’s a testament to your passion for the sea. Choosing the right bottom paint is a crucial step in ensuring it remains your faithful companion on countless voyages. With a keen understanding of the types of bottom paint and a thoughtful consideration of your boating style and environment, you can set sail confidently, knowing your boat is as ready for adventure as you are. Keep your hull in prime condition, and the sea will always welcome you with open arms.

RELATED ARTICLES

Overview of the 2024 sea-doo rxp-x 325, overview of the 2024 parker offshore 2900 cc, what your boat’s beam is and why it matters, power cats of 2024: ultimate guide to the top power catamarans this year, navigating the heat: 10 safety tips for a safe boat ride in the summer heat, latest posts, don't miss, our newsletter.

Get the latest boating tips, fishing resources and featured products in your email from BoatingWorld.com!

What type of wood is used for pier pilings?

What is the difference between a dock and a floating pier, what is the proper technique for pulling a beginner wakeboarder, what does ‘no wake’ mean on a lake, what is the difference between wash and wake, highs, lows, and tidal know-how: a deep dive into ocean currents, 10 essential tips for fishing near private property, the benefits of using a drift sock: guidance for anglers, lure fishing: secrets for imitating live bait and attracting fish, explore the untapped depths of america’s best bass fishing spots, outboard motor maintenance: tips for keeping your engine in top shape, the essential boat tool kit: tools every boater needs, diy boat building: 8 tips and tricks for building your own vessel, the art of miniature maritime craftsmanship: ship in a bottle, antifouling paints: a guide to keeping your boat shipshape, beginner’s guide to standup paddle boarding: tips and techniques, boating for fitness: how to stay active on the water, kayak safety: how to stay safe on the water, anchoring in a kayak or canoe: how to secure your small boat, overview of the 2024 yamaha 252sd, overview of the 2024 tiara yachts 48 le, overview of the 2024 bass cat jaguar sts, 2024 pursuit os 445: an overview, 2024 aquila 47 molokai review, 2024 sea-doo switch 13 sport review, gear reviews, megabass oneten max lbo jerkbait review, fortress anchors fx-7 anchoring system review, fortress anchors fx-11 anchoring system review, fortress anchors commando anchor kit review, fortress anchors aluminum anchors review, stay in touch.

To be updated with all the latest news, offers and special announcements.

- Privacy Policy

Free Shipping On All Orders!

- Epoxy Resins

- Polyester Resin

- Urethane Resins

- Epoxy Project Supplies

- Antifouling Paints

- Topside Paints

- Thinners & Solvents

- Paint Supplies

- Wood Oils & Finishes

- Wood Finishing Supplies

- Cleaning & Polishing

- Accessories

Table Top Epoxy

Clear High Performance Epoxy Kits

5:1 Traditional Epoxy Resin Kits

- Thinners & Solvents

Wet Edge Topside Paint

Premium Marine Topside Primer

Spartan Multi-Season Antifouling Paint

- Wood Finishes

- Wood Oils & Finishes

Gleam Marine Spar Varnish

Lust Rapid Recoat Marine Spar Varnish

Halcyon Water-Based Marine Varnish

TotalBuff Rubbing Compound

TotalShine Finishing Compound

White Knight Fiberglass Stain Remover

- TotalBoat Gear

FlexFit Fitted Mesh Back Baseball Cap

Men’s Long Sleeve T-Shirt Hoodie

Women’s Long Sleeve T-Shirt Hoodie

FREE SHIPPING with a minimum puchase of $1,200.00 You are $10.00 away from your free shipping!

Shipping, taxes, and dicount codes calculated at checkout.

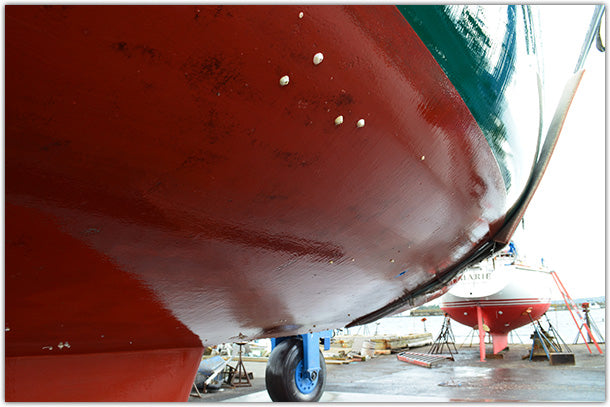

BOTTOM PAINTING

As a boat owner, getting dragged to the depths of the ocean by a giant sea monster is probably not high on your list of concerns. But make no mistake, there are some very foul creatures lurking beneath the waves.

We’re talking microscopic sea monsters: acorn barnacles, zebra mussels and slime-causing bacteria that cause serious hull drag, and wallet drain from higher fuel costs and repair bills.

You may not even know they’re there until it’s too late because they don’t come at you flailing ferocious tentacles, at least not ones you can see. What you will see—and want to prevent—is the ugly, dirty, slimy mess they make on the bottom of your hull that decreases your speed and increases your fuel bill because your engine has to work harder. A fouled hull bottom is also a safety risk because it can decrease your ability to maneuver.

Battle the barnacles and other biofouling bottom huggers with the right bottom paint for smoother sailing.

Choosing an Antifouling Bottom Paint

Location, location, location, types of antifouling bottom paint, which bottom paint is best for your boat, figuring how much paint you need, how to strike a waterline on your boat, bottom painting equipment, surface prep for bottom painting, best conditions for bottom painting, bottom painting like a pro.

The purpose of applying antifouling bottom paint is to prevent hard biofouling organisms like mussels, barnacles, and tubeworms, and soft growth like weeds and algae (slime!) from attaching to your hull below the waterline.

There are several different antifouling coatings available, with new ones being formulated all the time, making it very difficult to choose the paint that’s right for your boat and your budget. Some coatings work better in different locations, including fresh or salt water. Some are more environmentally friendly than others, and some cost more based on the type of biocide and the protection they provide.

The key antifouling ingredient in bottom paint is some type of biocide for deterring hard marine growth. Some antifouling paints also include an algaecide for preventing soft growth.

Biocide basics : For centuries, some form of copper has been used successfully to prevent the attachment of barnacles and other marine growth on hull bottoms. Today, the type of copper most commonly contained in antifouling paint is either cuprous oxide or cuprous thiocyanate. Cuprous thiocyanate has the added benefits of being a lighter copper in terms of color, so it produces brighter, truer paint colors. Also, paints using cuprous thiocyanate use half the amount of copper used in conventional, heavier cuprous oxide paints.

Because copper in the concentrations used in antifouling paints is a potential threat to some marine ecosystems, there are now equally effective, eco-friendly, antifouling paints that contain a metal-free biocide called Econea™ (main ingredient is tralopyril). Econea’s main benefit is that it dissolves after it is shed into the water, leaving no byproduct to harm marine life. Its secondary benefit is that it allows for the creation of brightly colored paints, unlike bottom paints containing cuprous oxide as the biocide.

Algaecide basics: If you use your boat in an area where slime, algae, and grass growth on the bottom of your hull are common, you need an antifouling paint that also contains an algaecide to prevent this soft growth. In the past, some antifouling paints contained an algaecide called Irgarol, which is no longer being used. Irgarol was discontinued because of its persistence after release into the water, and harmful effects on marine life. Zinc pyrithione (Zinc Omadine™) is now the slime-fighting agent used in many antifouling bottom paints. Its effectiveness is similar to Irgarol, but it dissipates quickly and harmlessly into marine or fresh water ecosystems. Zinc pyrithione is found in chemical solvent-based and water-based antifouling marine paints.

Chemical solvent-based or water-based antifouling paint? Another consideration is the type of solvent in the paint. Solvents keep the biocide, algaecide (if included), and pigment suspended in the paint so they’re distributed evenly in the coating as it’s applied to the hull surface. In the past, most antifouling paints contained harsh chemical solvents, and required the use of chemical solvents for thinning and cleanup. Those harsh chemical solvents contain toxic VOCs (volatile organic compounds) that evaporate easily into the atmosphere. To help meet environmental regulations in some areas of the country, and the world, there are now water-based paints, that also use water for thinning and cleanup. Many of these water-based antifouling paints contain the biocide Econea, and zinc pyrithione as the algaecide, because both dissolve in the water after release.

Won’t a water-based antifouling paint just dissolve and leave the hull unprotected while the boat is in the water? : The short answer is no. As the water-based paint cures, the water evaporates, leaving behind a protective film of biocide and/or algaecide, and pigment.

Teflon and vinyl bottom paints : Teflon paints are expensive, dry quickly, cure to a very thin film, and are ideal for fresh water areas where algae is a problem. Vinyl bottom paints are hard bottom paints that can be burnished smooth for racing, and are especially effective in saltwater, though not as effective as ablative paints for battling biofouling organisms. Both Teflon and vinyl bottom paints are used more to enhance performance, as in race boats, instead of antifouling.

Proprietary two-part bottom coatings : These products are new and expensive, using patented chemical formulas to create a hard and very slippery biofilm that doesn’t allow living organisms to attach to the boat.

Deciding on bottom paint is a regional, sometimes section-of-the-harbor-specific choice. It’s based on lots of variables like water temperature, silt, substrate, pollution, water flow, biofouling organisms present, and the frequency and type of boating you do.

Making that choice is made even harder because a bottom paint that works in one part of the harbor may not be as effective a few hundred yards away in that same harbor–even on the same type of boat.

The general consensus is there’s more fouling activity in warmer water and still water, and less growth in water that’s colder or where there’s more current flowing beneath the hull. It’s also harder for biofoulers to attach to a moving target, so the more you use your boat, the cleaner the bottom should remain.

At any rate, it’s always a good idea to ask fellow boaters and local boatyard professionals to help pinpoint paints that work best where your boat floats.

Bottom paints are usually one of two types: hard or ablative, with variations whose effectiveness depends on how much time the boat spends in the water, and how often it moves.

Hard bottom paints are typically less expensive than ablative antifouling paints. However, hard paints are effective for a single season, and they build up season after season, eventually requiring costly removal. Ablative paints come in single-season and multiseason varieties and don’t build up.

Hard bottom paint dries hard, stays that way, and doesn’t wear away gradually like an ablative paint. It works constantly while the boat is in the water, regardless of whether the boat is moving, and stops working once all its copper biocide gradually leaches out. So the coating can still be in great shape, but the biocide is gone and so is the protection. Water can seep in to the unprotected coating and damage the hull. Also, because hard bottom paint doesn’t wear away, it builds up and eventually has to be removed–a costly, labor-intensive endeavor.

Another problem for hard bottom paints is they lose their copper faster–and their effectiveness–if the boat is kept out of the water more than 60 days after applying bottom paint. For this reason, hard bottom paint is typically used on boats that remain in the water for extended periods. It’s also great for boats operated at faster speeds, like racing boats, because it can be burnished to increase hull smoothness and speed, unlike ablative bottom paints.

Ablative bottom paint wears away gradually as water flows under the hull, either from use or tidal movements. As the paint wears away, it exposes a fresh burst of biocide to keep biofoulers from attaching to the surface. There are ablative paints for multiple season use, and others that are effective for a single season. The single-season ablatives are typically less expensive than the multiple season ablatives.

For most ablative paints to work effectively, motion is required, so this paint is best if you use your boat fairly often–at least once a week. A hull painted with a single-season ablative antifouling paint can be pulled and left out of the water up to two weeks, but will require a light scuffing with a Scotch-Brite pad to reactivate the antifouling properties directly prior to launching.

A hull coated with a multi-season ablative can be pulled and left out of the water up to two weeks, without scuffing to reactivate the antifouling. However, after two weeks, scuffing is required directly before launching.

Self-polishing, copolymer ablative bottom paint also wears away gradually to expose fresh layers of biocide. However, it’s effective whether or not the boat is moving because it uses a self-polishing, controlled-release, copper copolymer formula. Some copolymer ablatives can last multiple seasons, requiring only a light scuffing to reactivate the antifouling in the spring, directly before launching.

Hybrid copolymer ablative bottom paint has all the self-polishing, controlled-release biocide benefits of a copolymer ablative. The difference is that it can also be burnished–like a hard bottom paint–for smoothness and speed, unlike other ablative bottom paints. And there’s less buildup to remove next season, as with hard bottom paints.

Preventing biofouling is not a one-shot-and-you’re-done deal, and no bottom paint is best for every boat. Your decision depends on answers to these practical questions.

What type of hull do you have? Most bottom paints contain copper as their antifouling biocide, which is fine for wooden, and fiberglass/gelcoat hulls, but causes galvanic corrosion, which will destroy a pontoon boat or an aluminum hull. For use on aluminum hulls, aluminum bottom paint typically uses a copper-free biocide such as Econea. Underwater metals such as outdrives and trim tabs also need this metal-free antifouling paint. And don’t forget the bottom of your inflatable, it needs protection, too. Inflatable bottom paint is ablative, so it wears away gradually, and is designed not to crack or peel while the boat is being rolled up, or after drying. What kind of water is your boat sitting in, and what’s the water temperature? In terms of temperature, biofouling levels are typically higher in warmer waters than cooler waters. Fresh water biofouling, while not as severe as saltwater (marine) biofouling, still poses problems which are compounded if the water is brackish or polluted. By far the biggest challenge comes from hard, marine biofouling organisms such as zebra mussels and barnacles, which destroy the hull surface and allow moisture in, causing blistering and other expensive damage. If moderate to heavy fouling is a problem in your region, you might consider a bottom paint that offers greater protection and lets you haul and relaunch without repainting, such as a multi-season paint. In lower fouling waters, you can get adequate single-season protection from a more economical bottom paint . The copper biocide (cuprous oxide or cuprous thiocyanate) or copper-free biocide (Econea) in these paints is designed primarily to combat hard shell marine growth. If slime is a problem in your area, use a slime-shedding bottom paint boosted with a slime-fighting agent (zinc pyrithione) that controls slime growth at the waterline. How and when do you use your boat? For example, do you trailer your boat? If so, you should use a harder ablative bottom paint that can withstand trailering. Do you race it or just like to go fast? Try a hybrid copolymer ablative that allows you to burnish the surface, and provides good single or multiple season protection. Do you go out every weekend? Every day? Do you want to be able to do your bottom painting at the end of the season so you’re ready to launch first thing in the spring? At TotalBoat, we’re DIY boaters that create products to suit every type of use in all types of waters. Do you live in an area that restricts the use of solvent and copper-based bottom paints? To address ever-increasing environmental regulations, some ablative bottom paints are now water-based and/or copper-free, containing an environmentally friendly biocide called Econea™, and fewer volatile organic compounds (VOCs). Other water-based ablatives contain copper for added antifouling protection, but offer easy soap and water cleanup. How much money do you want to spend on bottom painting? With bottom paint, usually the more biocide, or different types of biocide, the greater the cost. Also certain properties, like self-polishing, single or multi-season effectiveness, or slime-fighting ability, require the inclusion of certain additives, which can increase the cost. If you don’t need it, you shouldn’t have to pay for it, which is why we created a complete line of bottom paints to balance every boater’s needs and budget.

Figuring out the approximate surface area (in square feet) of your hull below the waterline is a good way to determine the amount of bottom paint you’ll need. Here’s an easy formula to use:

Length x Beam x .85

How heavily you apply the bottom paint is another factor in determining the quantity. The amounts below assume you want to coat the surface as thickly as possible without causing runs, and that you are applying two coats. For specific quantities, always refer to the manufacturer’s details on coverage areas.

| 14′ outboard | 1-2 quarts |

| 18′ runabout | 2 quarts |

| 20′ sailboat | 3 quarts |

| 24′ runabout | 3-4 quarts |

| 30′ sailboat | 1.5 gallons |

| 32′ cruiser | 1.5-2 gallons |

| 36′ auxiliary | 2 gallons |

| 40′ sailboat | 2.5 gallons |

| 45′ sailboat | 3-3.5 gallons |

| 50′ sportfisher | 4+ gallons |

Applying two coats of bottom paint up to the old waterline is a fairly straightforward task–if you know where the waterline is. Sometimes the line gets covered up by topside coatings, or it needs to be raised as the boat gets outfitted for cruising. Or you may have a new boat and need to find the waterline. Here’s a simple way to mark the waterline on your boat in preparation for bottom painting.

What You’ll Need for Bottom Painting

The safest and best way to do a DIY bottom paint job involves applying the paint with a brush or roller. Due to the substantial toxic hazards, spraying is not recommended.

If using a solvent-based antifouling paint, it’s important to use solvent-resistant roller covers, brushes, and paint trays and liners because the solvents in bottom paint are strong enough to dissolve regular household-type versions of these painting tools.

- Personal protection for sanding – paint suit with hood , goggles, and a respirator with appropriate cartridges, and gloves

- If bottom paint is cracking and peeling or otherwise requires removal (as in the case of hard bottom paint) use chemical stripper to remove it. Our TotalBoat TotalStrip paint remover is safe for gelcoat and fiberglass, and it’s easy to apply, odor-free, biodegradable, can strip up to 25 layers in a single application, requires no acid wash neutralization, and cleans up easily with just plain water. It’s also very effective on bottom paint.

- If previous bottom paint is in good condition and not too thick (only a couple of previous coats), you don’t need to sand it down, just scuff it up using a clean, maroon Scotch-Brite pad

- Paint scraper for removing loose or chipping antifouling paint to clean up the hull bottom before sanding

- When sanding down old bottom paint, use 80-grit large diameter sanding disks and a right angle grinder or dustless sander (recommended). 80-grit paper is the most common grit for sanding antifouling paint. Always use a dustless sander to keep the toxic antifouling paint sanding residue contained.

- Masking tape – solvent and water-resistant tape is ideal for lengthy bottom painting jobs that require two coats. This clean-release masking tape lifts off easily, leaving no gummy residue.

- Scratch-free cleaning and wiping rags and acetone or mineral spirits for removing surface dust and residue

- Solvent-resistant paint brush or 3/8" nap roller, paint tray and liner, plus small-width chip brushes for cutting in

- Drop cloths for any sanding debris, and for catching paint drips and spills

To ensure the best possible bond and the most effective antifouling results, take time to assess the type and amount of surface preparation needed. Typically, most ablative bottom paints can be applied over hard paints, but not the other way around. Also most other antifouling paints can’t be painted over vinyl or Teflon bottom paints. Incompatible paints must be removed first. Substrate matters, too, so for example, if you’re painting on steel or aluminum, check that you coat the surface with an appropriate metal primer first. Incompatible bottom paint or previous bottom paint that is extremely deteriorated should be stripped first. Use a chemical stripper that works with bottom paint to remove it. If you stripped the old antifouling and found hull damage or damage to the barrier coat, or if you’re painting a new boat for the first time, you’ll need to apply an epoxy barrier coat before applying bottom paint.

Cleaning Tips

In many cases, you’ll be painting over a previous bottom paint job that’s in good condition, so you don’t need to strip the paint or sand. Just chip away any loose paint with a paint scraper or putty knife, then abrade with a medium-grade 3M ScotchBrite pad, then wipe the surface with a clean, lint-free cheesecloth, rag, or tack cloth dampened with acetone or mineral spirits (or thinner recommended by the paint manufacturer) to remove residual dust and grease, let dry, then apply masking tape.

Sanding Tips

If you need to sand, sanding makes a mess, so first lay down some drop cloths under and around your work area. Sanding bottom paint also creates toxic dust, so use a dustless sander. And protect your exposed eyes, skin, and lungs with high-quality protective equipment before you begin sanding.

Masking Tips

For the cleanest line, try to position the tape as close to the bootstripe as you can, beginning at a natural start point in the line. Draw the tape out slowly, outlining every 1.5 to 2 feet. In addition, mask around underwater metals to protect them from contact with any copper-based antifouling paint.

Use 80-grit sandpaper to sand the entire bottom to smooth it out and remove any high or uneven spots. Sand lightly so you don’t sand through a protective barrier coat or damage gelcoat. After sanding, wipe down the surface using the solvent recommended by the bottom paint manufacturer.

After masking, and before painting, wipe the surface with a clean, lint-free cloth to remove any residual dust or dirt.

Getting great performance from your antifouling paint takes more than just completing the surface prep properly so the paint has every chance to bond mechanically and chemically to the hull. You also have to apply the paint when the timing is right in terms of temperature and humidity.

Resist the urge to start painting until temperatures are between 50°-85°F and the humidity is between 65 and 90%, or according to the manufacturer’s specifications. Be patient and wait for the weather to cooperate. You’ll be rewarded not just with optimal antifouling effectiveness, but with better looking, longer lasting results.

Before you start, pay attention to the dry time between coats and the recommended number of coats, as indicated by the manufacturer. Also, be sure to check if there are any maximum limits on the amount of time the boat can remain out of the water after bottom painting and prior to launch. For example, copolymer ablative paints dry faster, which means their overcoating times are shorter. They also have longer or unlimited launch windows.

Once you know the characteristics of your coating, and you’re ready to paint, here are some tips to expedite the process.

- To make it easier to get as much copper off the bottom of the can and into the paint, take it to a paint shop and have it shaken first. This will make it easier for you to stir the paint thoroughly.

- Do not thin bottom paint or it will lose its antifouling effectiveness.

- Use a solvent-resistant brush or 3/8" nap roller to apply paint thickly, without drips, onto the hull. Keep the thickness even, and paint from one end of the boat to the other.

- Because ablative paints wear away faster in areas of greatest turbulence, apply extra coats to these places such as the leading edge of the keel and the bow.

- Remember to paint underwater metals such as transducers, with a copper-free antifouling paint that will not cause galvanic corrosion.

- Recoat based on the manufacturer’s directions for overcoat times. Ensure that the weather conditions are optimal for recoating.

- After the final coat of bottom paint has dried, remove the masking tape slowly and carefully. After cleaning up, be sure to dispose of used solvent and paints properly.

- Choosing a selection results in a full page refresh.

ACTIVE STORM TRACKER Hurricane and Tropical Storm Information Learn more

Service Locator

- Angler Endorsement

- Boat Towing Coverage

- Mechanical Breakdown

- Insurance Requirements in Mexico

- Agreed Hull Value

- Actual Cash Value

- Liability Only

- Insurance Payment Options

- Claims Information

- Towing Service Agreement

- Membership Plans

- Boat Show Tickets

- BoatUS Boats For Sale

- Membership Payment Options

- Consumer Affairs

- Boat Documentation Requirements

- Installation Instructions

- Shipping & Handling Information

- Contact Boat Lettering

- End User Agreement

- Frequently Asked Questions

- Vessel Documentation

- BoatUS Foundation

- Government Affairs

- Powercruisers

- Buying & Selling Advice

- Maintenance

- Tow Vehicles

- Make & Create

- Makeovers & Refitting

- Accessories

- Electronics

- Skills, Tips, Tools

- Spring Preparation

- Winterization

- Boaters’ Rights

- Environment & Clean Water

- Boat Safety

- Navigational Hazards

- Personal Safety

- Batteries & Onboard Power

- Motors, Engines, Propulsion

- Books & Movies

- Cockpit Confessions

- Communication & Etiquette

- Contests & Sweepstakes

- Colleges & Tech Schools

- Food, Drink, Entertainment

- New To Boating

- Travel & Destinations

- Watersports

- Anchors & Anchoring

- Boat Handling

- ← Maintenance

Applying Bottom Paint

Advertisement

Preparation required for a successful bottom job begins as soon as the hull clears the water.

Slime and growth are relatively easy to remove while the bottom is still wet, but let the stuff dry and you will have to chisel it off. Fortunately most boatyards pressure wash the bottom as soon as they haul the boat, and many will also knock off hard growth with a long-handled scraper. If bits of bottom paint flake off under the pressure of the washer nozzle, ask the yard worker to make another pass to remove as much loose paint as possible.

Remember that the adhesion of the new paint is only as good as that of the paint under it, so watch for signs of adhesion failure. Anywhere the old paint is flaking or lifting, worry exposed edges with a knife or small chisel. If the paint zips off, the bottom needs to be stripped.

You may also have to strip the bottom if you are changing the type of paint. For example, the aggressive solvents in vinyl paints lift other types of bottom paints, so if you are applying vinyl, any non-vinyl paint has to come off. And soft, sloughing paints are a poor undercoat for anything other than a fresh coat of the same.

Using a 2-inch hook scraper is the stripping method least injurious to both you and the planet, and this is often the easiest method as well. If you decide to use a chemical stripper, be sure it is one formulated for fiberglass; regular strippers will attack the gelcoat.

When the old paint is in good condition, in general you need only sand it, wash it, tape the waterline, and roll on a fresh coat or two. A grinder loaded with 80-grit disks on a foam pad can quickly prepare a hull for recoating, but it can also chew through the paint and into the laminate in an instant. If you lack experience with this powerful tool, 80-grit paper in a random orbit sander or a finishing sander will do the same job somewhat less quickly but with much less risk to the hull. Do not use a belt sander; it is designed to make things flat and that is the effect it will have on your hull.

Many boatyards now prohibit normal power sanding because of the dust it generates. The solution is a shop-vac and a random-orbit sander with a vacuum hose connection. If you don't want to buy a new sander, slip a length of plastic hose over the dust bag mount on your old palm sander and tape the other end into the shop-vac hose. Either rig will capture most of the toxic dust sanding generates, but not all of it. Be sure to wear a tight-fitting respirator — not a paper mask — while sanding. Also wear earplugs to shut out the din of the sander and the vac. You'll save your hearing and find the work much less tiring.

Even if you aren't stripping the bottom, it is good practice to sand away most of the previous application. This avoids a thick build-up that will eventually turn brittle and cause new paint to flake. A different color first coat provides a flag that signals when you have sanded enough.

Bare Fiberglass

A hull that has not been previously painted has mold release wax on the fiberglass that will interfere with paint adhesion unless you remove it. Clean the hull surface thoroughly with dewaxing solvent and plenty of clean rags before you sand; otherwise sanding drags the wax into the scratches and it will be that much harder to remove.

Sand the de-waxed hull lightly with 80-grit paper before applying the first coat of paint — the flag coat — which should be a different color from the top coat(s).

If the boatyard has a paint shaker, run it for at least 5 minutes to get the copper and the pigment evenly distributed throughout the paint. A drill-powered mixing paddle can also do a good job. In the absence of a either, pour half the paint into a mixing bucket so you can mix the remaining half vigorously without sloshing paint onto the ground. Keep dredging up the copper off the bottom of the can until the bottom feels clean to the touch of your paddle. Slowly stir in what you poured off until the paint is uniform in color and consistency. If the paint has been on the shelf awhile, getting it mixed thoroughly can take 10 or 15 minutes, but don't skimp; if the copper isn't evenly distributed, some areas of your hull won't be protected.

Roll the paint onto the hull using a short-nap roller cover. An extension for the handle will make painting the keel easier and keep you clear of the inevitable droplets the roller will sling. Wear sleeves and gloves to keep the paint off your skin.

Don't add any thinner to bottom paint unless the manufacturer specifies otherwise. (There are exceptions to every rule: thinner may be required if the day is hot and windy.)

Fill the basin of your paint tray with paint. Dip your roller, unload it on the tray slope, and roll it up and down on the hull, i.e. from waterline to keel. Work fast as many bottom paints dry quickly. Each time you refill the paint tray, first stir the paint in the can to keep the copper in suspension.

By the time you work all the way around the hull, many bottom paints will be dry enough to overcoat. Check the specifications on the paint you are using. A second coat lengthens the life of almost any bottom paint; copolymers benefit from 3 or 4 coats. No sanding or other prep is needed between coats. Save some paint for the areas under the stand or cradle pads.

Get the yard manager to move the stands as soon as the rest of the hull is dry (never move stands yourself!), and put rags or sheet plastic on the pads to protect your new paint. Prep the bare spots and apply the appropriate number of coats. Save a little paint to slap on the areas on the bottom of the keel you can't get to until the boat is lifted.

Prop and Shaft

You can paint the prop if you like, but copper-based paint won't stay on a bronze prop (nor bronze rudders and struts) for long. Prop paints are available, but demanding prep — up to four prime coats — discourages their use. A heavy coat of wax on the prop will keep it clean for a time.

Don't paint the shaft, and be sure you leave all anodes unpainted. If you are installing new anodes — a good idea — make certain you don't paint over their mounting locations. Good electrical contact is essential for anodes to do their job.

Let bottom paint dry at least overnight before you put masking tape on it to paint the bootstripe. Get hard bottom paint into the water within the time specified on the label.

For more information about painting, consult Sailboat Refinishing by Don Casey

Related Articles

The truth about ceramic coatings for boats.

Our editor investigates the marketing claims of consumer-grade ceramic coatings.

Fine-Tune Your Side Scan Fishfinder

Take your side-scanning fishfinder off auto mode, and you’ll be spotting your prey from afar in no time

DIY Boat Foam Decking

Closed-cell foam flooring helps make boating more comfortable. Here’s how to install it on your vessel

Click to explore related articles

Contributor, BoatUS Magazine

Don Casey has been one of the most consulted experts on boat care and upgrades for 30 years, and is one of the BoatUS Magazine's panel of experts. He and his wife cruise aboard their 30-footer part of the year in the eastern Caribbean. His books include Don Casey's Complete Illustrated Sailboat Maintenance Manual, and the recently updated This Old Boat, the bible for do-it-yourself boaters.

BoatUS Magazine Is A Benefit Of BoatUS Membership

Membership Benefits Include:

Subscription to the print version of BoatUS Magazine

4% back on purchases from West Marine stores or online at WestMarine.com

Discounts on fuel, transient slips, repairs and more at over 1,200 businesses

Deals on cruises, charters, car rentals, hotel stays and more…

All for only $25/year!

We use cookies to enhance your visit to our website and to improve your experience. By continuing to use our website, you’re agreeing to our cookie policy.

- New Sailboats

- Sailboats 21-30ft

- Sailboats 31-35ft

- Sailboats 36-40ft

- Sailboats Over 40ft

- Sailboats Under 21feet

- used_sailboats

- Apps and Computer Programs

- Communications

- Fishfinders

- Handheld Electronics

- Plotters MFDS Rradar

- Wind, Speed & Depth Instruments

- Anchoring Mooring

- Running Rigging

- Sails Canvas

- Standing Rigging

- Diesel Engines

- Off Grid Energy

- Cleaning Waxing

- DIY Projects

- Repair, Tools & Materials

- Spare Parts

- Tools & Gadgets

- Cabin Comfort

- Ventilation

- Footwear Apparel

- Foul Weather Gear

- Mailport & PS Advisor

- Inside Practical Sailor Blog

- Activate My Web Access

- Reset Password

- Customer Service

- Free Newsletter

The PDQ 32 Cruising Cat Used Boat Review

Dufour 44 Used Boat Review

Blue Jacket 40 Used Boat Review

Catalina 270 vs. The Beneteau First 265 Used Boat Match-Up

How to Create a Bullet-Proof VHF/SSB Backup

Tips From A First “Sail” on the ICW

Tillerpilot Tips and Safety Cautions

Best Crimpers and Strippers for Fixing Marine Electrical Connectors

Revive Your Mast Like a Pro

Solving the Dodger Dilemma

Polyester vs. Nylon Rode

Getting the Most Out of Older Sails

Sailing Triteia: Budget Bluewater Cruising

How To Keep Pipe Fittings Dry: Sealant and Teflon Tape Tests

Fuel Lift Pump: Easy DIY Diesel Fuel System Diagnostic and Repair

Propane Leak: How to Detect, Locate and Fix

Why Choose the Wharram Design?

Winterizing: Make It Easy With Checklists

Stopping Holding-tank Odors

Giving Bugs the Big Goodbye

Galley Gadgets for the Cruising Sailor

The Rain Catcher’s Guide

Sailing Gear for Kids

What’s the Best Sunscreen?

UV Clothing: Is It Worth the Hype?

Preparing Yourself for Solo Sailing

R. Tucker Thompson Tall Ship Youth Voyage

On Watch: This 60-Year-Old Hinckley Pilot 35 is Also a Working…

On Watch: America’s Cup

On Watch: All Eyes on Europe Sail Racing

Dear Readers

- Boat Maintenance

Picking the Best Bottom Paint

This month’s report on bottom preparation is another reminder that the most effective paint as determined by our past testing might not always be the best for your circumstances or location.

Unless you’re prepared for more prep work than a light sanding, the first step in selecting a bottom paint is finding one thats compatible with whats on your hull now. All of the manufacturers in our test will provide guidance on this, either over the phone or on the company website.

Generally, you can repaint a hard paint with either a hard or soft paint, while a soft ablative paint will need more sanding or a tie-coat primer when being coated with a hard paint. Bare fiberglass or metal will require a primer, and aluminum components like saildrives need a special copper-free paint that wont induce potentially disastrous galvanic corrosion.

Before paying more than $250 or more a gallon, consider your priorities.

Application: With no unpleasant solvents, water-based paints are the easiest and safest to apply.

The environment: Driven by legislation regulating copper loading in sensitive waters, this is a fast-growing field. In recent tests the copper-free blends from Epaint have proven the most effective in marine environments. This is good news for owners of aluminum boats, which are incompatible with most copper-laced paints. Freshwater boats will be pleased with some of the less expensive paints featured in this months report.

No paint buildup: Over time, ablative paints wear away; hard paints generally form thick layer cakes.

Quick recoating: Hard paints can take a second coat sooner than ablatives, although some of the newer copolymer ablatives can be recoated after four hours or less. Thin-film Teflon paints for racing boats can dry in a matter of minutes.

Haulout schedules: Some paints (typically hard paints) lose their effectiveness if not launched within a certain time frame, or if the boat is hauled out and then relaunched without painting. Some paints you need to lightly sand or scuff to reactivate before relaunching.

Trailerability: Some ablative paints are designed to resist abrasion from trailering. Most hard paints will trailer well, but not all are meant to dry out.

Color: Pettit Vivid, Interlux Trilux, and Blue Water Kolor offer broad palette choices. Typically, the low-copper paints (Epaint being an exception) offer more color choices. If potency is what you’re after, some makers suggest black, although our panel studies are inconclusive regarding this. Some brands (such as Pettit) put a little more copper in some of their red paints.

Want to be a part of our bottom paint testing program? Fill out this quick survey at https://goo.gl/qTbu6p so we can share your experience with other sailors.

RELATED ARTICLES MORE FROM AUTHOR

Boat Improvements for the Technically Illiterate

What Do You Do With Old Fiberglass Boats?

Leave a reply cancel reply.

Log in to leave a comment

Latest Videos

A Sailboat Tour of the Exquisite Little Harbor 63 Ketch

Dock and Anchor Lines – Polyester or Nylon?

The Performance Sailboat from Island Packet: Blue Jacket 40 Boat Review

Top 3 Winter Boat HACKS!

Latest sailboat review.

- Privacy Policy

- Do Not Sell My Personal Information

- Online Account Activation

- Privacy Manager

Please verify you are a human

Access to this page has been denied because we believe you are using automation tools to browse the website.

This may happen as a result of the following:

- Javascript is disabled or blocked by an extension (ad blockers for example)

- Your browser does not support cookies

Please make sure that Javascript and cookies are enabled on your browser and that you are not blocking them from loading.

Reference ID: 90e6ccde-7cf5-11ef-9cb2-9ee3caca1e84

Powered by PerimeterX , Inc.

IMAGES

VIDEO

COMMENTS

Rust-Oleum Marine Flat Boat Bottom Antifouling Paint. As one of the most respected brand names in the bottom paint industry, Rust-Oleum is known for producing some of the best sailboat bottom paint and the Marine Flat Boat Bottom Antifouling Paint is one of them. This bottom pain is designed to be suitable for various conditions (both ...

Now get to work! First, lay out a large tarp or dropcloth to cover the entire work area. Knock off any loose paint with a scraper and, using either a sanding block or a dustless DA sander, lightly sand the entire bottom with 80-grit sandpaper. Spend a little extra time on any high or uneven areas.

While Californias anti-copper push has stalled for now, the movement continues to gain momentum elsewhere. Last year, Washington state passed legislation prohibiting copper-based antifouling paint on new boats sold after 2018 and banning the use of bottom paints with more than 0.5-percent copper on recreational boats after 2020.

We presume these boats are being relaunched the following season without being repainted. Favorites from Interlux included: Micron 66, Micron Extra, Fiberglass Bottomkote NT, and ACT. Pettit paints popular in this region included the ablatives SSA, Vivid, and Hydrocoat, and the budget-priced hard paint Unepoxy.

Types of bottom paint include ablative antifouling paint, modified epoxy antifouling paint, hard vinyl and thin film paint. We also stock inflatable boat antifouling paint and transducer antifouling paint. Ablative antifouling paints derive antifouling effectiveness from the biocides they contain and from controlled wearing, which as a side ...

1. All bottom paint is the same. Nope. The basic coatings include three types. Hard paint is epoxy-based and releases a biocide constantly so it's considered "contact leaching.". It is durable, abrasion-resistant, and more finicky to apply as it usually is sprayed rather than rolled or brushed on.

This preventative maintenance task should be at the top of your list. A clean hull is safe, fast and efficient—while a fouled bottom will reduce your boat's speed, maneuverability and cost you more at the fuel dock. We'll give you a quick rundown on what antifouling paint does and 10 questions to ask yourself before buying.

Bottom painting is a vital aspect of boat maintenance, essential for protecting your vessel and ensuring optimal performance on the water. By following the steps outlined in this guide and considering important factors such as paint type, preparation, safety, and frequency of application, you can effectively maintain your boat's hull and ...

With a keen understanding of the types of bottom paint and a thoughtful consideration of your boating style and environment, you can set sail confidently, knowing your boat is as ready for adventure as you are. Keep your hull in prime condition, and the sea will always welcome you with open arms. January 23, 2024.

No paint buildup: Over time, ablative paints wear away; hard paints generally form thick layer cakes. Quick recoating: Hard paints can take a second coat sooner than ablatives, although some of the newer copolymer ablatives can be recoated after four hours or less. Thin-film Teflon paints for racing boats can dry in a matter of minutes.

This Boat Bottom Paint 101 guide describes the different types of antifouling bottom paints to help make your decision and purchase as pain-free as possible. When choosing antifouling paint, it's important to understand the advantages of the different types of antifoulants. There's much more to choosing bottom paint than just the price tag.

Refer to the paint manufacturer's details on coverage amounts (typically given in square feet per gallon). Here's an easy formula for figuring out the square footage of your hull below the waterline, where you'll be applying bottom paint. Length (in feet) x Beam (in feet) x .75. Here are some typical estimates for various types of boats.

You may use this paint on aluminum, fiberglass, wood, or steel boats in fresh and saltwater. You can also use it on outdrives, trim tabs, and other underwater metals. Krypton comes in five bright colors (blue, white, red, black and green) and is available in quarts or gallons. Coverage is 350-400 square feet per gallon.

May 22, 2013. The chances are that unless you have a small daysailer or dinghy that spends most of its time out of the water, your boat will have some form of antifouling paint below the waterline. Antifouling paint is poisonous to marine life and prevents it, as much as possible, from adhering to the bottom while the boat is in the water.

This will make it easier for you to stir the paint thoroughly. Do not thin bottom paint or it will lose its antifouling effectiveness. Use a solvent-resistant brush or 3/8" nap roller to apply paint thickly, without drips, onto the hull. Keep the thickness even, and paint from one end of the boat to the other.

Good electrical contact is essential for anodes to do their job. Let bottom paint dry at least overnight before you put masking tape on it to paint the bootstripe. Get hard bottom paint into the water within the time specified on the label. For more information about painting, consult Sailboat Refinishing by Don Casey.

The formula below works as an easy bottom paint calculator and all you need to know is your boat's length, the distance from bow to stern, and beam, the distance from side to side at the widest part of the boat. Length x Beam x .75 = Approximate Underwater Surface Area in Sq. Ft. Each paint has a "theoretical coverage" area, but most paints ...

All bottom paints contain and release some sort of toxic biocide that prevents critters such as barnacles and algae from hitching a ride on your boat's bottom. Today, cuprous oxide (copper) is the most common biocide you'll find in bottom paint, though some bottom paints contain cuprous thiocyanate or eco-friendly, barnacle-busting ...

Boat bottom paint is a specialized type of paint used to protect the hull of a boat from the damaging effects of saltwater, barnacles, and other marine growth. These paints work by creating a barrier between the boat's hull and the water, which helps prevent corrosion and other types of wear and tear. Many different brands of craft bottom paint ...

Eco-friendly bottom paints, anti-fouling paints, long-term performance reviews and more. You'll find it all in our annual Bottom Paint Test and Roundup. ... Practical Sailor takes the guesswork out of boat & gear buying with its bold, independent, product-test reports just for serious sailors. FOLLOW US. About Us; Subscribe; YouTube; Products ...

3027 Capital Blvd Ste 111 , Raleigh NC 27604-3399. home. categories. boat maintenance. boat paint & solvents. bottom paint & coatings. If you leave your boat in the water at least part of the year, keeping the hull free of marine growth with one or more coats of quality antifouling paint is critical to keep it performing its best—and for ...

No paint buildup: Over time, ablative paints wear away; hard paints generally form thick layer cakes. Quick recoating: Hard paints can take a second coat sooner than ablatives, although some of the newer copolymer ablatives can be recoated after four hours or less. Thin-film Teflon paints for racing boats can dry in a matter of minutes.

2.5 gal. 1 gal. Another way to determine how much paint you'll need is to estimate the approximate surface area of the hull below the waterline using the following formula: Length (From bow to stern) x Beam (The width of the boat, measured at its widest point) x .75 = Approximate Underwater Surface Area in Sq. Ft.